-

Home

-

About Us

-

Products

-

News

-

Application

-

Service

-

Blog

-

Contact Us

Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

-

Whatsapp

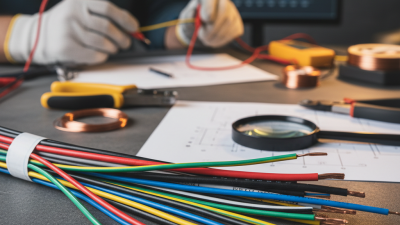

The landscape of Cable Wire Harness technology is rapidly evolving. Experts agree on its crucial role in various industries. John Smith, a leading expert in the field, states, "Innovation in Cable Wire Harness design is essential for future advancements."

As industries seek to enhance efficiency and sustainability, trends emerge in Cable Wire Harness solutions. Automation and smart technology are becoming integral. Manufacturers focus on lightweight materials, reducing costs and improving performance. However, challenges persist, as adapting to new technologies is not always seamless.

Reflection is necessary as we dive into the latest trends. Are we keeping pace with the evolving requirements of the market? The commitment to innovate in Cable Wire Harness technology will shape the future. It is a journey filled with opportunities and hurdles.

Cable wire harness technology is experiencing a significant transformation, driven by the demand for efficiency and reliability in various industries. According to a recent report by the Allied Market Research, the global cable harness market is expected to reach $38.24 billion by 2026, growing at a CAGR of 4.67%. This growth reflects the increasing adoption of advanced technologies aimed at improving automation and connectivity.

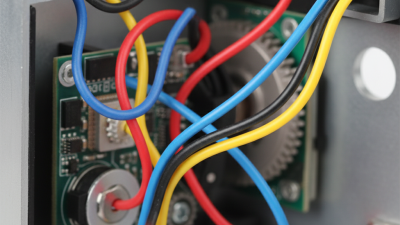

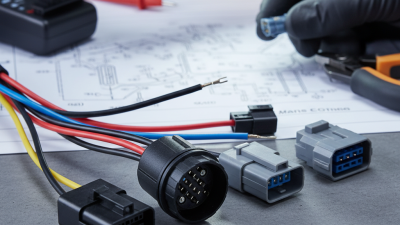

Innovations such as 3D printing in cable harness manufacturing are gaining traction. This technology allows for rapid prototyping and customization, reducing lead times. Moreover, the use of advanced materials, like lightweight composites, enhances durability. These materials can withstand extreme conditions, reducing failures due to environmental factors. However, challenges remain. The transition to these advanced materials needs thorough testing to ensure reliability and maintain safety standards.

As industries evolve, the integration of IoT in cable harness designs is becoming essential. Smart cable harnesses equipped with sensors can monitor performance in real-time. This capability offers unprecedented data insights. Yet, the security of such systems raises concerns. Ensuring data integrity is crucial to prevent cyber risks. Investing in robust security protocols is necessary to safeguard these innovations. The future of cable wire harness technology holds promise but requires careful consideration of these emerging challenges.

This chart illustrates the projected advancements in cable wire harness technology across various industries for 2026. The data showcases the growth trends in key areas such as automation, connectivity, and sustainability.

The automation of cable wire harness production is transforming the industry. In 2026, a significant shift is expected as companies adopt advanced technologies like AI and robotics. Reports indicate that automation can increase production efficiency by up to 30%. This boost allows manufacturers to meet rising demands while reducing labor costs. However, the transition is not seamless.

Many firms face challenges in integrating these technologies. A study revealed that only 40% of organizations successfully implemented automation in their production lines. Workers often resist automated systems, fearing job loss and skill obsolescence. Training and change management become crucial to overcome these hurdles. The human element remains vital in this tech-driven landscape.

Moreover, while automation enhances speed, it can lead to quality control issues. The reliance on machines magnifies any initial errors in the design phase. It’s essential to refine processes to maintain product integrity. Data suggests that even with automation, the inspection methodologies need improvement. In this evolving environment, finding a balance between human expertise and technology is critical for sustainable growth.

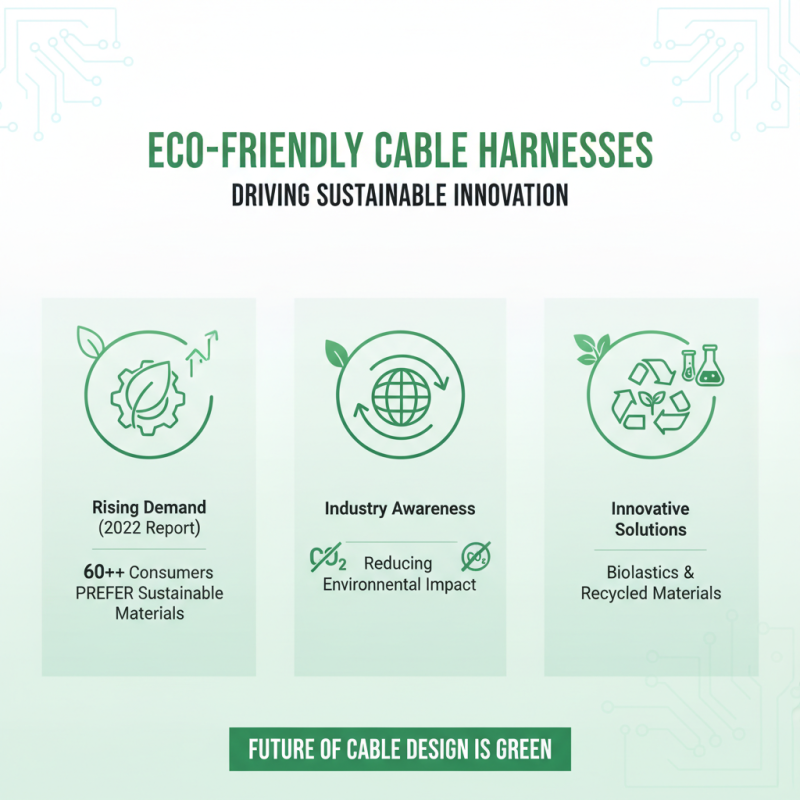

The demand for eco-friendly materials in cable wire harness design is rising. Industries are increasingly aware of their environmental impacts. A 2022 report indicated that over 60% of consumers prefer products made from sustainable materials. This growing preference drives innovation in the sector. Manufacturers are exploring bioplastics and recycled materials to create more sustainable solutions.

Using biodegradable polymers is one promising trend. These materials can reduce waste and minimize environmental harm. Companies have started experimenting with these alternatives to meet consumer demands. However, sourcing these eco-friendly materials can be challenging. They may not always match traditional materials in performance. This aspect requires careful testing and improvements.

Incorporating recycled materials presents another opportunity. A 2023 study found that using recycled plastics can reduce carbon footprints by up to 40%. Yet, achieving consistent quality remains a concern. Manufacturers need to ensure reliability and safety while embracing sustainability. Balancing performance and eco-friendliness is crucial for future innovations.

The Internet of Things (IoT) is reshaping the cable wire harness industry. IoT technology enhances wire harness functionality in various ways. Sensors embedded in harnesses collect real-time data. This data provides insights into performance and potential issues. For example, a wire harness in an automotive application can monitor temperature and electrical flow. It allows manufacturers to predict failures before they occur, reducing downtime.

Tips: Regularly update software systems linked to IoT. Ensure that data security measures are in place to protect sensitive information.

Another significant aspect involves remote monitoring. With IoT, wire harnesses can be monitored from anywhere. This capability is vital for industries like aerospace and healthcare. Moreover, it promotes faster decision-making processes. However, challenges remain regarding reliability and compatibility. Integrating new technology with existing infrastructure can be complex.

Tips: Test new IoT solutions in controlled environments. Analyze the data carefully before full-scale implementation.

Overall, the role of IoT in wire harness technology is promising. Innovations bring efficiency, but they require careful planning and execution. Addressing the potential drawbacks will ensure long-term success in the industry.

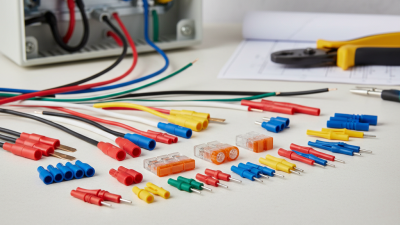

| Trend | Description | Impact on Industry | Projected Growth (%) |

|---|---|---|---|

| IoT Integration | Employing IoT technology to monitor the wire harness performance in real-time. | Improving operational efficiency through proactive maintenance. | 25% |

| Smart Materials | Usage of flexible and lightweight materials that respond to changing environments. | Enhanced durability and reduced weight, leading to better energy efficiency. | 15% |

| Advanced Assembly Techniques | Utilization of robotics and automation for high-precision assembly. | Increased production efficiency and reduced labor costs. | 20% |

| Eco-friendly Solutions | Development of sustainable materials and recycling processes. | Meeting regulatory standards and reducing environmental impact. | 30% |

| Enhanced Connectivity | Improved connectors and interface for better signal integrity. | Improving performance in high-speed applications. | 18% |

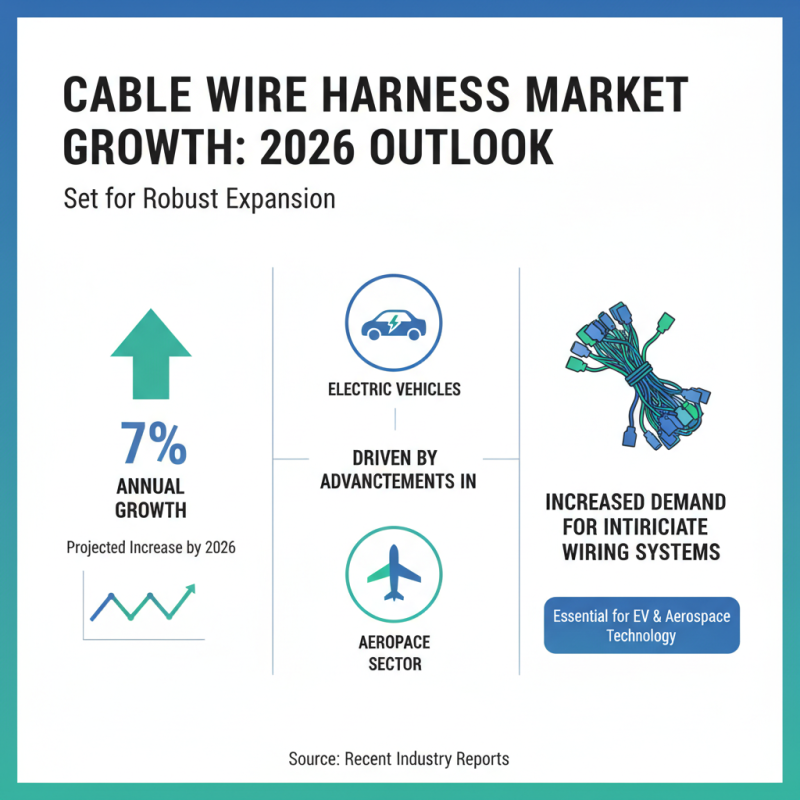

The cable wire harness market is set for robust growth by 2026. Recent reports indicate a projected increase of 7% annually. This rise is attributed to advancements in automotive and aerospace sectors. For example, the increased adoption of electric vehicles has created a surge in demand. Electric vehicles require intricate wiring systems, making wire harness technology essential.

Data shows that the automotive segment will contribute the most to market growth. By 2026, it is expected to account for 40% of the total market share. However, challenges exist. Manufacturers are grappling with the complexity of designs. The push for lighter and more efficient materials complicates production.

In the aerospace industry, the demand for lightweight harnesses is on the rise. These components are critical for safety and performance. Reports indicate a growth rate of 5% in this sector. Nevertheless, high production costs might limit some innovations. Balancing quality with cost remains an ongoing dilemma for manufacturers.