-

Home

-

About Us

-

Products

-

News

-

Application

-

Service

-

Blog

-

Contact Us

Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

-

Whatsapp

In today's technology-driven world, the use of Flexible Flat Cables (FFCs) has become increasingly vital. According to a report by Markets and Markets, the global flexible flat cable market is expected to reach approximately $2 billion by 2026. This growth is driven by the demand for compact and lightweight wiring solutions in various electronics, such as smartphones and laptops.

Expert engineer Richard Thompson, a leading voice in the FFC industry, emphasizes, “The future of electronics relies on the flexibility and efficiency of Flat Cables.” His insights highlight how FFCs not only save space but also enhance performance. With various applications, there’s much to consider when choosing the best options available.

While many options exist, not all FFCs might suit specific needs. It's crucial to ponder what flexibility truly means in practical applications. The nuanced characteristics of these cables can sometimes be inconsistent. Educating oneself about their properties and variations can be beneficial. As the market continues to expand, a careful selection process is essential for optimal performance in electronics.

Flexible flat cables (FFC) are essential in modern electronics. They provide a compact solution for connecting multiple components. These cables are thin, lightweight, and highly adaptable to various spaces. Their flexibility allows for easy installation in tight areas, making them ideal for mobile devices and compact machinery.

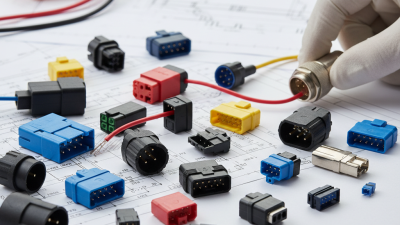

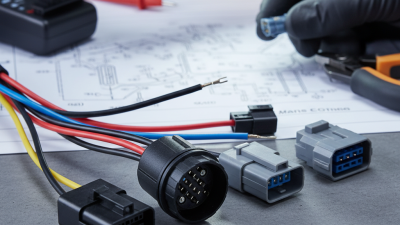

Different applications use flexible flat cables, ranging from consumer electronics to industrial equipment. They have become a favorite in laptops, cameras, and even automotive systems. The versatility of these cables aids in minimizing space and improving organization within devices. However, manufacturers must pay attention to factors like durability and stability when choosing materials.

While flexible flat cables offer numerous benefits, they also present challenges. Connecting them requires precision. A poor connection can lead to device malfunctions. Users should also consider the cable's bending limits. Over time, excessive bending might cause fatigue. Thus, careful planning is essential for effective use.

This chart displays the performance of the top 10 flexible flat cables measured in megabits per second (Mbps). Flexibility and performance vary across different cable types, making them suitable for various electronic applications.

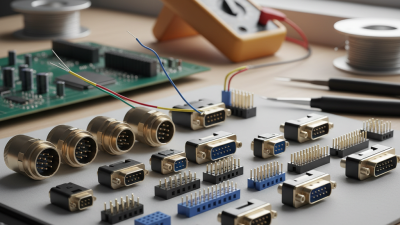

When selecting flexible flat cables for electronics, several key factors emerge. The conductor material plays a crucial role. Copper is often favored for its excellent conductivity, while aluminum can be lighter but offers lower performance. According to a report by the International Electrotechnical Commission, cables made with high-quality materials can enhance signal integrity and reduce power loss.

Another important consideration is the cable thickness and width. Thinner cables provide more flexibility, making them ideal for compact devices. However, they may not support high current applications effectively. A study from the Institute of Electrical and Electronics Engineers shows that properly dimensioned cables yield better efficiency and longevity.

Insulation type is another factor worth noting. PVC, for example, is common but may not withstand high temperatures well. Teflon provides better heat resistance but can be costly. Balancing costs with performance often leads to difficult decisions. Manufacturers sometimes face trade-offs, where a cheaper option may affect overall durability or performance.

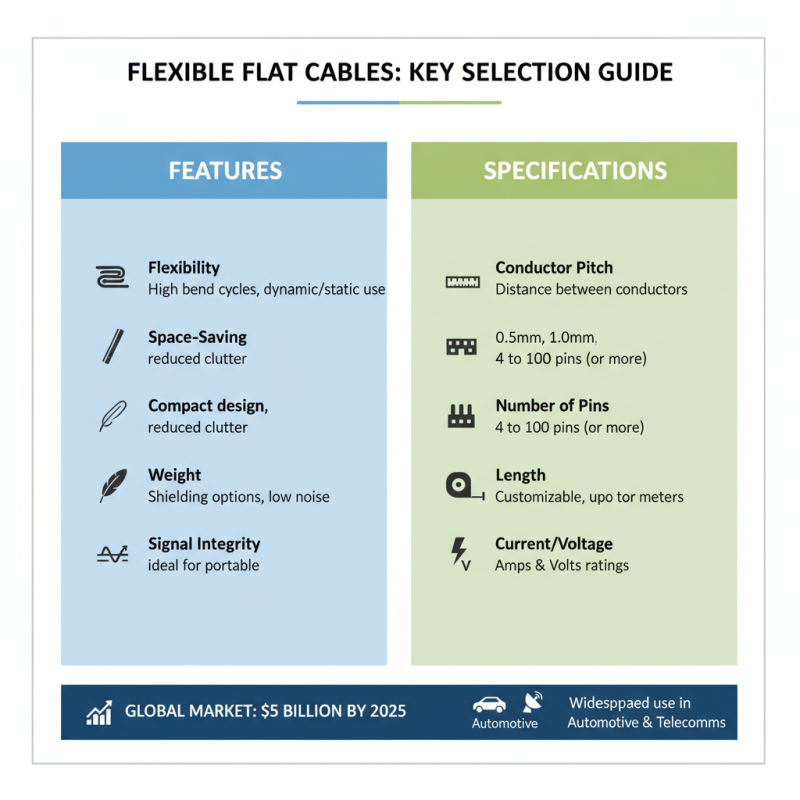

When selecting flexible flat cables, compare features and specifications closely. Flexible flat cables, often used in electronics, serve various applications. A report by ResearchAndMarkets indicates that the global flexible flat cable market will reach $5 billion by 2025. This growth reflects widespread usage in sectors like automotive and telecommunications.

Key specifications matter. Pay attention to thickness and material. Polyimide and PVC are popular choices. The cable's flexibility is critical for tight spaces. A well-designed cable can handle bending stress without breaking. Many users overlook bend radius, which is crucial for longevity.

Another aspect to consider is the number of conductors. Cables typically range from 2 to 64 conductors. More conductors mean more functionality but also complexity. Test data shows that cables with fewer conductors tend to perform better in terms of signal integrity. Yet, achieving the right balance can be challenging. Understanding your specific needs is essential. Match cable specifications with project requirements.

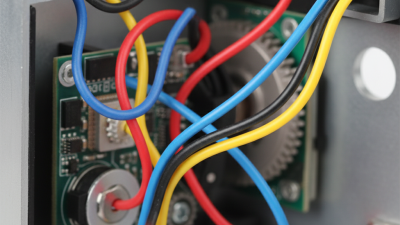

When working with flexible flat cables (FFC), proper installation is key. The flexibility and thinness of FFC make them ideal for compact electronic devices. However, their installation requires careful attention to detail. Industry reports suggest that incorrect installation can lead to a 40% increase in failure rates.

Tip: Always ensure proper alignment of the cable with the connection points. Misalignment can cause issues during operation. Additionally, make sure the cable is free from any bends or kinks. These can create stress points, leading to potential failures over time.

For improved durability, consider using proper connectors. This can enhance connectivity and reduce the risk of damaging the cable. Industry data indicates that well-chosen connectors can extend the lifespan of FFC by up to 30%. Regular inspections can also help identify wear and tear early on.

In conclusion, while flexible flat cables offer great advantages, the installation process must be executed with precision. Small mistakes can lead to significant setbacks in performance. It's crucial to invest time in a meticulous setup.

Flexible flat cables are essential for a variety of electronics. Proper maintenance can significantly extend their lifespan. Start by regularly inspecting the cables for any signs of damage. Look for fraying or wear at the ends. These areas are often the most vulnerable.

Cleaning is crucial. Use a soft, dry cloth to wipe away dust and dirt. If needed, slightly dampen the cloth with water or a mild cleaning solution. Avoid soaking the cable, as excess moisture can lead to issues. Additionally, be careful when bending the cables. Excessive bending may create weak points that could fail later.

Storage is another important aspect. Keep cables in a dry environment, away from sharp objects and heat sources. Coiling them loosely can prevent kinks and potential breaks. Don't ignore these details; they can make a difference over time. Regular care ensures your flexible flat cables remain reliable and efficient.

| Rank | Cable Type | Length (m) | Conductor Material | Shielding | Recommended Use |

|---|---|---|---|---|---|

| 1 | FFC | 0.5 | Copper | No Shielding | LCD Displays |

| 2 | FFC | 1.0 | Tin-Plated Copper | Foil Shielding | Cameras |

| 3 | FPC | 1.5 | Copper | No Shielding | Robotics |

| 4 | FFC | 2.0 | Copper | Foil Shielding | Industrial Equipment |

| 5 | FPC | 0.8 | Copper | No Shielding | Smartphones |

| 6 | FFC | 1.2 | Tin-Plated Copper | Braided Shielding | Computers |

| 7 | FPC | 1.0 | Copper | No Shielding | Wearable Devices |

| 8 | FFC | 1.4 | Copper | Foil Shielding | Audio Equipment |

| 9 | FFC | 2.5 | Copper | Braided Shielding | High-End Computers |

| 10 | FPC | 1.8 | Copper | No Shielding | Gaming Consoles |