-

Home

-

About Us

-

Products

-

News

-

Application

-

Service

-

Blog

-

Contact Us

Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

-

Whatsapp

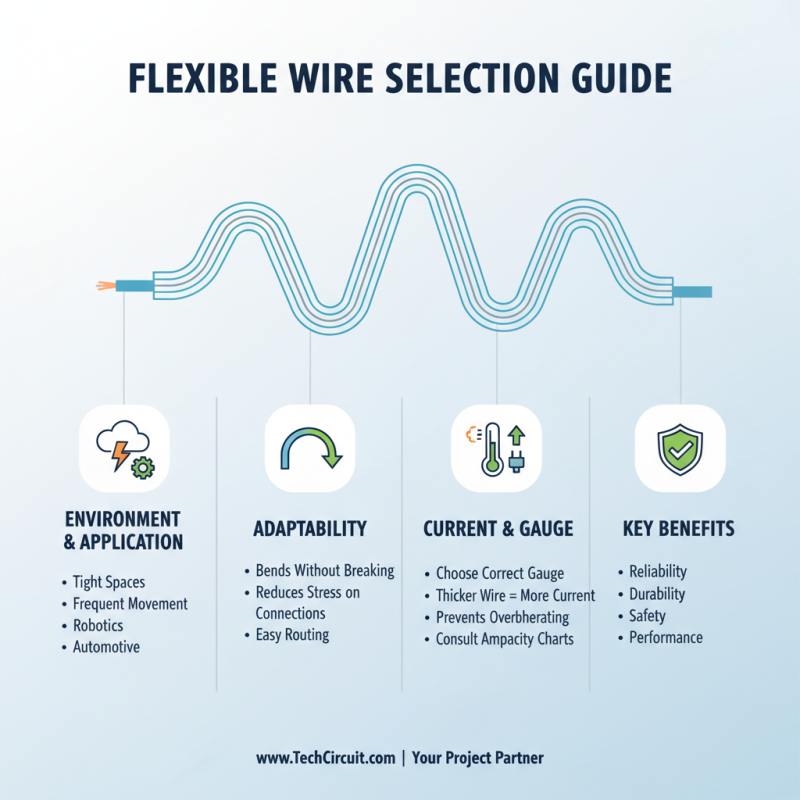

Choosing the right materials for your projects is crucial. One compelling option is Flexible Wire. This versatile component offers numerous advantages. Its adaptability sets it apart in various applications.

Flexible Wire is designed to bend and twist without breaking. This feature is invaluable in tight spaces. It allows for easy installation in intricate designs. Think of electronics or automotive projects where limited space is common. Difficult angles often arise, and flexible solutions are vital.

However, it’s worth noting that not all companies provide high-quality Flexible Wire. Some products may not withstand harsh conditions. Therefore, careful research is necessary before purchasing. Choosing the right supplier can make a significant difference. Flexibility is not just a feature; it’s a necessity in today’s innovative landscape.

Flexible wire is essential for various projects, particularly in electrical and construction work. It is made to bend without breaking, allowing for easy handling and installation. The flexibility enables it to fit into tight spaces where rigid wires cannot. This adaptability is especially crucial in areas requiring intricate wiring solutions.

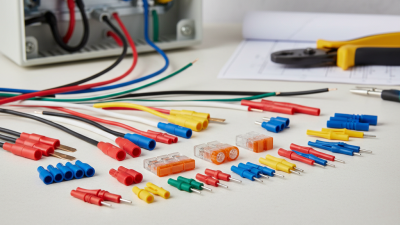

There are several types of flexible wires available. Stranded wire consists of multiple small wires twisted together, providing excellent flexibility. Another type is the braided wire, which is made of many thin wires woven together. Both types are ideal for different applications, such as automotive or industrial uses.

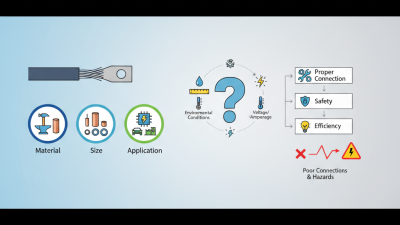

Tips: When choosing flexible wire, consider the intended use. Always check the specifications for voltage ratings. Remember, thicker wire may not always be better. Sometimes, a lighter gauge fits the application perfectly. Test your connections frequently. A loose connection can cause serious issues later on. Always prioritize safety when working with electrical components.

Flexible wire is essential for a range of projects due to its adaptability. It bends easily, making it ideal for tight spaces. This feature allows for creative designs that rigid wires cannot accommodate. Whether you are working on electronics or home wiring, flexibility can enhance your approach.

One notable advantage is its resistance to breakage. Traditional wires may snap under stress. In contrast, flexible wire can endure repeated movement. This characteristic is especially important in devices with moving parts. Projects often require durability, and flexible wire provides that reliably. However, it's wise to ensure the correct gauge is used. Choosing the wrong one can lead to performance issues.

Another key point is the ease of installation. Flexible wire often simplifies complex setups. It can be cut to size and manipulated easily. Despite these benefits, some might find its handling tricky. It may entangle or kink if not managed properly. Understanding the nuances of flexible wire can lead to better results in your projects.

| Advantage | Description | Applications |

|---|---|---|

| Flexibility | Easily bends and conforms to different shapes and spaces. | Home wiring, prototypes, and equipment installations. |

| Durability | Resistant to wear, moisture, and corrosion, ensuring longevity. | Outdoor and industrial applications. |

| Ease of Installation | Simplifies wiring processes, reducing installation time. | DIY projects and large installations. |

| Electrical Performance | Efficient conductivity with minimal resistance. | Electronics and electrical equipment. |

| Versatility | Can be used in various applications across industries. | Lighting, automotive, and telecommunications. |

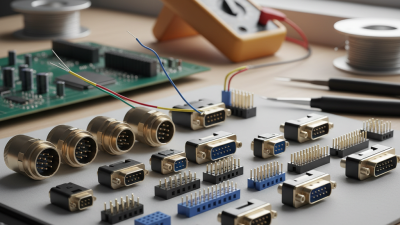

Flexible wire is widely used across various industries due to its adaptability and strength. In the automotive sector, it connects complex electronic systems. These wires can bend without breaking, making them ideal for tight spaces. They allow for efficient energy transfer and signal integrity. Motors and sensors rely on flexible wire for reliable performance.

In the construction industry, flexible wire plays a crucial role in electrical installations. It accommodates movements in buildings, preventing damage. This is essential for high-rise structures and areas susceptible to vibrations. The flexibility ensures safety and longevity of electrical systems. While it is beneficial, improper installation can lead to issues. Understanding the proper techniques is vital for success.

Flexible wire also finds applications in medical devices. It enables intricate connections within tools and machines. Precision and reliability are non-negotiable here. Yet, the challenge lies in maintaining performance over time. Regular monitoring is important, as wear and tear can affect functionality. Overall, flexible wire serves diverse purposes, but its application requires careful consideration.

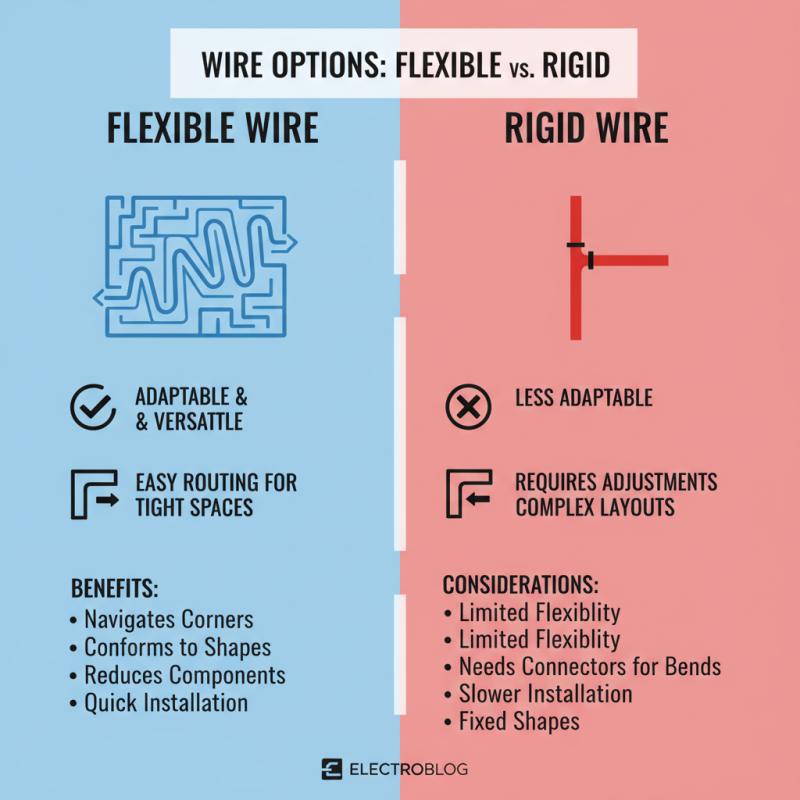

When considering wire options, it's crucial to weigh the benefits of flexible wire against rigid alternatives. Flexible wire offers versatility unmatched by its rigid counterpart. It can navigate tight corners and adapt to various shapes. Rigid wire lacks this adaptability, often requiring adjustments or additional components for complex layouts.

In practical applications, flexible wire can simplify installations. Whether in home entertainment systems or intricate electronic devices, it molds to the space available. Rigid wire, on the other hand, can limit creativity. It may lead to frustrating moments when specific angles or configurations are needed. The rigidity can result in unnecessary workarounds.

While flexible wire seems superior, it has its downsides. Sometimes, the increased flexibility can lead to tangling during installation. If not managed carefully, this can slow down the project. Moreover, flexible wires may require more attention to secure them properly. With proper planning and awareness of these challenges, choosing flexible wire can lead to more efficient and innovative project outcomes.

When selecting flexible wire for your projects, consider the environment and application. Flexible wire is ideal for tight spaces and areas with frequent movement. It adapts well to bending without breaking. Choose the right gauge to prevent overheating. Thicker wire can handle more current but may be less flexible.

Installation requires attention to detail. Use proper connectors to ensure secure connections. Improper fittings may lead to failures, even in seemingly minor applications. Make sure to test the wire after installation. A simple continuity test can save you from future headaches.

Pay attention to insulation types. Some materials are better suited for specific environments. If you're working near water, choose a waterproof insulation. If the wire will endure high temperatures, look for heat-resistant options. Small mistakes can have big consequences, so plan carefully and think critically about every choice you make.