-

Home

-

About Us

-

Products

-

News

-

Application

-

Service

-

Blog

-

Contact Us

Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

-

Whatsapp

In the world of electronics, choosing the right components is crucial. Male Female Header Pins are essential for ensuring proper connections in circuits. As John Smith, an industry expert, stated, “The right header pins can make or break your project.” This highlights the importance of selection.

When selecting Male Female Header Pins, consider several factors. The size, pin count, and compatibility with your applications are vital. You don’t want to end up with pins that don’t fit or function as intended. Visualizing the project’s setup can clarify your needs.

Many overlook the difference between quality and cost. Sometimes, cheaper options lead to failure. Reflection on past experiences can guide better choices. It’s essential to balance budget and reliability. Trust your instincts, but also do your homework. The right Male Female Header Pins ensure that your projects succeed.

When selecting male and female header pins for your projects, understanding the basics is crucial. Male pins are often used as connectors. They come with a protruding shape, making them easy to plug into sockets. Female headers, on the other hand, are designed to receive these male pins. They provide stability and secure connections.

Choosing the right pin type can affect the overall functionality of your project. Not all pins fit every header. It can be frustrating to find that your pins do not align properly. This mismatch often leads to loose connections or faulty signals. Paying attention to pin pitch, or the distance between pins, can help prevent these issues.

One might think that more pins are always better. However, adding too many can complicate your design. It’s important to balance functionality and simplicity. Make sure to have a clear layout before finalizing your pin choice. Reflecting on your specific needs will lead to better decisions in your projects.

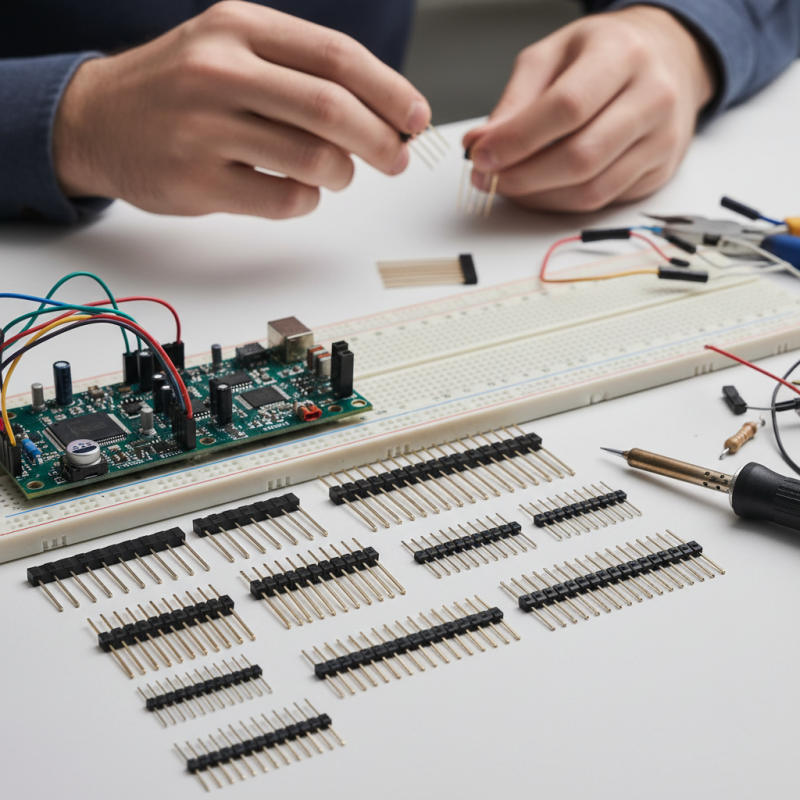

Choosing the right header pins for your projects begins with identifying specific requirements. Different projects have unique needs. Understanding these can save time and effort. For instance, consider the pin configuration. Are you working with a circuit board or a connector? Pin spacing and layout are crucial.

Tips: Think about the environment. Will the pins be exposed to moisture or varying temperatures? Selecting materials that resist corrosion can enhance durability. Pay attention to pin sizes as well. Some projects may require smaller pins, while others may need larger ones. Precision is key.

Additionally, assess the electrical specifications. What is the voltage and current rating? Ignoring these can lead to failures. Compatibility with existing components is also essential. Testing different pin types can help refine your choice. Sometimes, the most straightforward solution may not work. Reflect on past projects to avoid previous mistakes.

| Criteria | Description | Example Values |

|---|---|---|

| Pin Size | Consider the physical size needed for your project. | 2.54mm, 5.08mm |

| Material | Choose based on conductivity and durability. | Brass, Tin-plated |

| Gender Type | Determine if you need male, female, or a combination. | Male, Female |

| Number of Pins | Decide how many connections are required. | 2 pins, 4 pins, 8 pins |

| Current Rating | Select based on the maximum current your project can handle. | 3A, 5A |

| Temperature Rating | Consider the operational temperature range. | -20°C to +85°C |

When selecting header pins for electronic projects, material options play a crucial role. Metal, plastic, and alloy materials each have unique benefits. Metal pins often provide better conductivity and durability. They perform well in challenging environments. However, they can also corrode over time. A 2021 industry report suggested that over 30% of manufacturers faced issues with metal fatigue in header pins.

Plastic options are lighter and more cost-effective. They are resistant to moisture and corrosion. However, they may not conduct electricity as well as metals. According to a recent study, nearly 25% of projects using plastic header pins experienced connection failures. This raised concerns about their reliability in critical applications.

Alloy header pins combine the advantages of both metal and plastic. They can offer superior strength while being resistant to corrosion. Although they can be more expensive, their longevity can justify the cost. Over 40% of engineers reported improved performance when switching to alloys. This highlights the need for careful material selection in projects. The right choice can making or break the functionality of your designs.

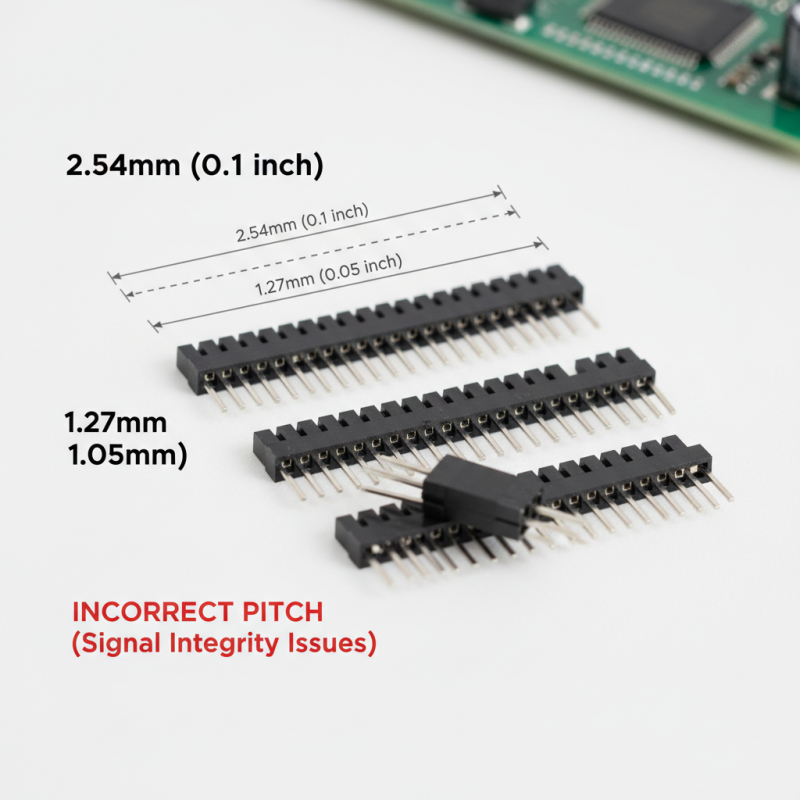

When selecting male and female header pins, compatibility is crucial. Evaluating pin pitch and size can significantly impact the success of your projects. Pin pitch refers to the distance between the centers of two adjacent pins. Standard pitches include 2.54mm (0.1 inch) and 1.27mm (0.05 inch). According to industry reports, using incorrect pin pitch can result in poor connections and signal integrity issues. This can lead to failed projects and wasted resources.

Size also plays a vital role in ensuring effective connections. Standard sizes for header pins usually range from 2.0mm to 20mm in length. The choice of size may depend on the specific application and available space on the PCB. A mismatch can lead to difficulties in insertion or soldering. The Electronic Industries Alliance states that nearly 20% of designs face integration failures due to poor size selection. Always consider physical limitations and component compatibility to avoid complications.

Reflecting on these factors is essential. Designers often rush the selection process, leading to preventable mistakes. Ensure you check the specifications and documents related to your components. Investing time in evaluating these details often pays off. Understanding the nuances of pin pitch and size can mean the difference between project success and costly errors.

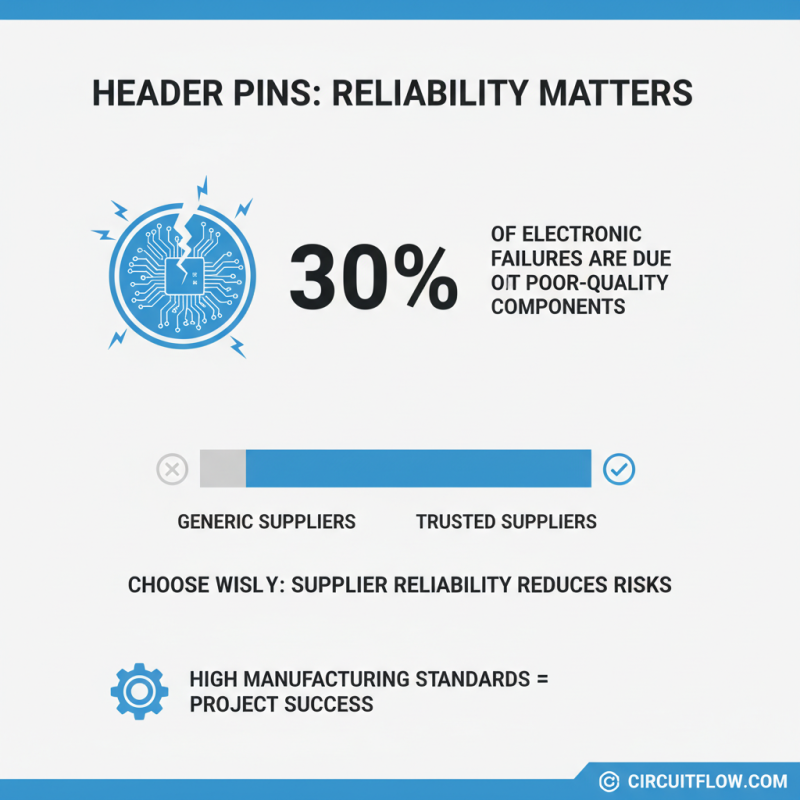

When selecting header pins for your projects, the supplier's reliability is crucial. According to recent industry reports, nearly 30% of electronic failures can be traced back to poor quality components. This statistic emphasizes the importance of choosing a supplier that adheres to high manufacturing standards.

Look for suppliers that provide certifications such as ISO 9001. This assures quality management and consistency. Engage with vendors who offer detailed product specifications. This includes materials used, pin dimensions, and current ratings. Keep in mind that the specification should match your project's requirements to avoid potential issues.

Also, consider the supplier's customer service. Studies show that 40% of companies prioritize reliable support when selecting vendors. Prompt responses can save time and reduce project delays. It is essential to read reviews and testimonials, even if they are imperfect. A few negative comments can offer valuable insights into potential shortcomings. Trust is built through transparency and accountability in communications.