-

Home

-

About Us

-

Products

-

News

-

Application

-

Service

-

Blog

-

Contact Us

Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

-

Whatsapp

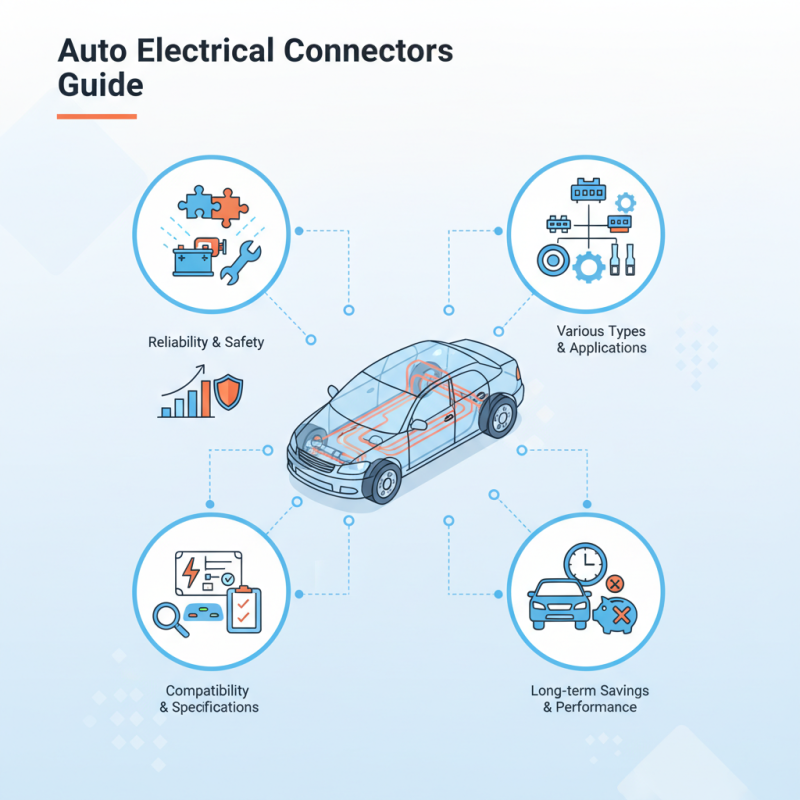

Choosing the right auto electrical connectors is crucial for any vehicle owner. According to industry expert John Smith, “Using quality connectors ensures reliability and safety on the road.” Auto Electrical Connectors play an essential role in a vehicle’s electrical system. They connect various components and ensure smooth functionality. When selecting connectors, you must consider the specific requirements of your vehicle.

The world of Auto Electrical Connectors can be tricky. Numerous types exist, each designed for different applications. A common mistake is assuming all connectors are the same. Many people overlook the importance of compatibility, which can lead to issues later. Poor choices may result in electrical failures, compromising performance and safety.

Understanding the specifications of Auto Electrical Connectors is vital. It’s not just about finding connectors that fit; it's about selecting dependable options suited to your vehicle’s needs. Reflecting on the right choice will save time and costly repairs down the line. Ultimately, a thoughtful approach will ensure a well-functioning electrical system in your vehicle.

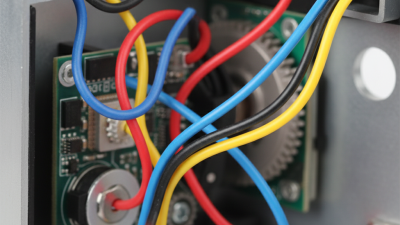

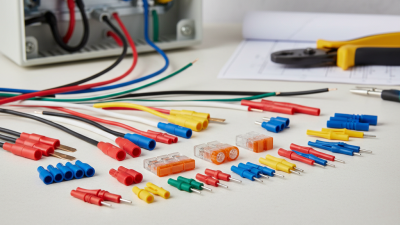

When choosing auto electrical connectors, understanding the types available is crucial. There are several key categories: terminal connectors, wire-to-wire connectors, and wire-to-board connectors. Terminal connectors, for instance, are widely used for their reliability in various applications. According to a recent market report, about 45% of automotive connectors fall into this category.

Wire-to-wire connectors are essential for creating secure connections between two wires. They come in various configurations, including splices and plugs. These connectors often facilitate quick repairs, saving valuable time during maintenance. Data suggests that the global demand for these connectors will grow significantly, potentially reaching $8 billion by 2027.

Wire-to-board connectors serve a specific purpose in connecting a wire to a printed circuit board. They are often found in modern vehicles equipped with advanced electronics. Despite their advantages, many users overlook the importance of proper selection. Common mistakes include choosing connectors with inadequate voltage ratings or environmental resistance. Such oversights can lead to failures in crucial systems. Understanding the unique features of each connector type is essential for optimal vehicle performance.

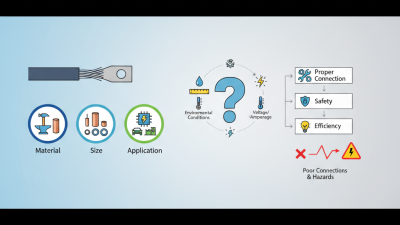

When selecting auto electrical connectors, compatibility with your vehicle's electrical system is critical. Start by checking the existing connectors. Note their shapes, sizes, and pin configurations. Mismatched connectors can lead to failures. You might end up with loose connections or shorts. This can be frustrating and costly to fix later.

Consider the material of the connectors. Ensure they can withstand the environment in which they'll be used. Look for corrosion resistance, especially in humid or salty areas. It's essential to choose connectors that fit securely. A loose fit is a common mistake. Reflect on how you plan to use your vehicle. Regular use in harsh conditions requires more robust connectors.

Don't forget to check the voltage rating of the connectors. Using parts not rated for your system can lead to malfunctions. Sometimes, connectors may appear compatible but aren’t. Visual inspection is not enough. It's wise to consult vehicle manuals or online resources for guidance. If you find yourself uncertain, seek assistance. A small mistake can lead to bigger issues down the line.

| Connector Type | Material | Current Rating (Amps) | Temperature Range (°C) | Seal Type |

|---|---|---|---|---|

| Blade Connector | Copper | 20 | -40 to 125 | Unsealed |

| Ring Terminal | Tin-Plated Copper | 30 | -40 to 105 | Sealed |

| Bullet Connector | Brass | 15 | -40 to 130 | Unsealed |

| DT Connectors | Plastic | 50 | -55 to 105 | Sealed |

| Molex Connector | Nylon | 20 | -40 to 85 | Unsealed |

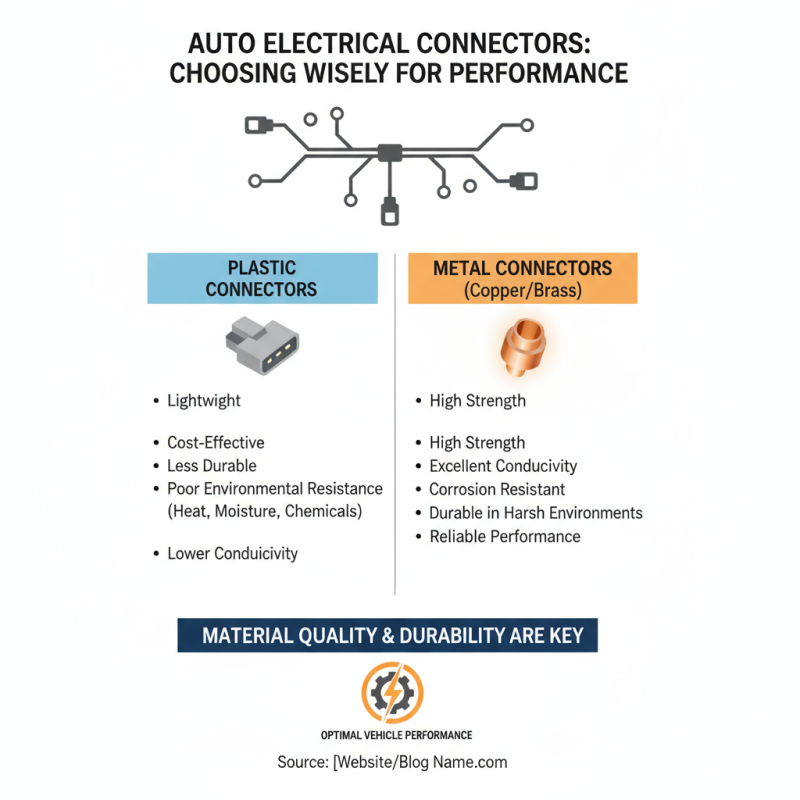

Choosing the right auto electrical connectors is crucial for vehicle performance. When evaluating connectors, material quality and durability are key factors. Plastic connectors may be lightweight, but they often lack resistance to environmental factors. Metals, like copper, offer better conductivity and strength.

Always inspect the connector’s specifications. Look for ratings that indicate temperature resistance and corrosion protection. These ratings provide insight into how well the connectors will perform in challenging situations. Durable materials can prevent frequent replacements.

Tip: Consider the application of your connectors. For outdoor use, choose materials that can withstand moisture and extreme temperatures.

Another tip: consult with a specialist. Get insights on which materials best suit your vehicle type and usage. Uninformed choices can lead to poor performance. Ensure that you are making decisions based on lasting quality instead of just cost. This will save hassle in the long run.

Choosing the right size and configuration for auto electrical connectors is crucial. It can impact the efficiency of your vehicle's electrical systems. A quick assessment of your vehicle's wiring needs is essential. Focus on the gauge of the wire you are using. This often dictates the connector size. Match the connector to the wire. If the wire is too thick, the connector might not fit properly. This could lead to loose connections.

The configuration plays a vital role too. Different connectors serve specific purposes. Some connectors are designed for high voltage applications, while others handle lower voltage. Also, consider the environment. If the connector is exposed to moisture, select a weatherproof version. Think about the ease of installation as well. Some connectors are easier to work with than others. Fumbling with connections in tight spaces can be frustrating.

Don't forget to visualize the final setup. Imagine where each connector will sit within your vehicle. This will help you determine the right lengths and angles. It’s easy to make mistakes in the selection process, especially if you rush. Reviewing your choices and double-checking specifications can save time and effort later. Take a step back and ensure every detail is accounted for. Each connection matters.

This chart illustrates the distribution of various types of auto electrical connectors based on their common usage in vehicles. Understanding the size and configuration can help you make informed decisions when selecting the right connectors.

When it comes to auto electrical connectors, choosing reliable manufacturers is crucial. Trusted suppliers often offer detailed product information. Look for companies that have a reputation for quality. Reviews from other customers can provide insights. See how long they have been in the industry. Experience often indicates reliability. Make sure they comply with industry standards. Check if they conduct quality tests regularly.

It's beneficial to attend automotive trade shows or conventions. These events highlight reputable manufacturers and innovative products. You can ask questions and inspect connectors firsthand. Networking with industry professionals can also provide recommendations. Pay attention to the materials used in connectors. High-quality materials usually lead to improved performance and durability.

Reflect on your specific needs. Sometimes, cheaper options may lack the reliability required for your vehicle. Investing in quality connectors can save you from future issues. Consider the technical support offered by suppliers. Good service can help troubleshoot problems later on. Take your time with this decision. The right connector can enhance your vehicle’s overall performance.