-

Home

-

About Us

-

Products

-

News

-

Application

-

Service

-

Blog

-

Contact Us

Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

-

Whatsapp

Choosing the right Electrical Connectors is crucial for any project. A recent industry report highlights that improper selection can lead to failures, costing companies significant time and resources. The global market for Electronic Connectors is expected to reach $80 billion by 2026, reflecting their critical role in modern technology.

With numerous options available, decision-making can be overwhelming. Various types cater to specific applications, but many engineers grapple with compatibility. Each use case may require unique specifications, such as current capacity or environmental durability. Missteps in this area are common and can derail projects.

The stakes are high when it comes to Electrical Connectors. Quality connections ensure reliability in devices, especially where safety is concerned. Reflecting on past experiences might reveal how a poor choice affected performance. Identifying what to prioritize is key. Understanding the nuances can lead to better outcomes in the long run.

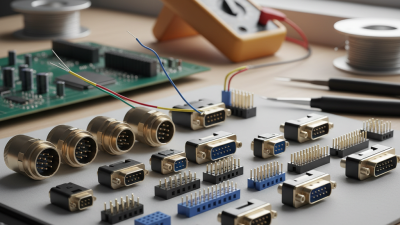

When selecting electrical connectors for a project, it's essential to understand the various types available. Connectors vary in design, size, and purpose. Some common types include tethered, modular, and heat shrink connectors. Each type serves specific applications, such as automotive, industrial, or home use. Make sure to consider the requirements of your project carefully.

Taking time to research different connectors can save headaches later. Look at the current and voltage ratings. Think about the environment where the connector will be used. Will it face moisture, heat, or vibration? Make choices that align with these conditions.

Tips: Always check compatibility with existing components. Look for user reviews and get advice from professionals. Don’t rush the decision-making process. Sometimes, trial and error will help refine your choices. Keep track of what works and what doesn’t. Noting these details can lead to better decisions in the future.

| Connector Type | Description | Applications | Rated Voltage (V) | Current Rating (A) |

|---|---|---|---|---|

| Wire-to-Wire | Connects two wires directly allowing power or signals to pass. | Automotive, Home Appliances | 600 | 30 |

| Wire-to-Board | Connects wires to a printed circuit board. | Computers, Medical Devices | 300 | 20 |

| Board-to-Board | Connects two PCBs together. | Consumer Electronics, Telecommunications | 500 | 10 |

| Circular Connectors | Utilizes a circular design for rugged applications. | Industrial Equipment, Aerospace | 1000 | 50 |

| USB Connectors | Standardized interface for data transfer and power. | Computing Devices, Mobile Phones | 5 | 3 |

Choosing the right electrical connectors is crucial for any project. Various factors can influence your decision. Understanding these key aspects is vital to achieving reliable connections.

Material is one significant factor. Connectors can be made from metals like copper or aluminum. The choice of material affects conductivity and resistance to corrosion. If you're in a humid area, consider corrosion-resistant options.

Another aspect to ponder is the connector type. Options include plug and socket, spade, or terminal types. Each type has specific applications. Ensure compatibility with your devices. A poor choice could lead to connection issues down the line.

Tips: Always double-check the voltage ratings. A mismatch can cause failures. Take time to ensure proper gauge sizes. Too thick or too thin can compromise safety.

Furthermore, the environment plays a role. If your project is outdoors, opt for weatherproof connectors. They can withstand exposure to elements, reducing maintenance needs in the future. Reflect on your project's unique demands to make an informed choice.

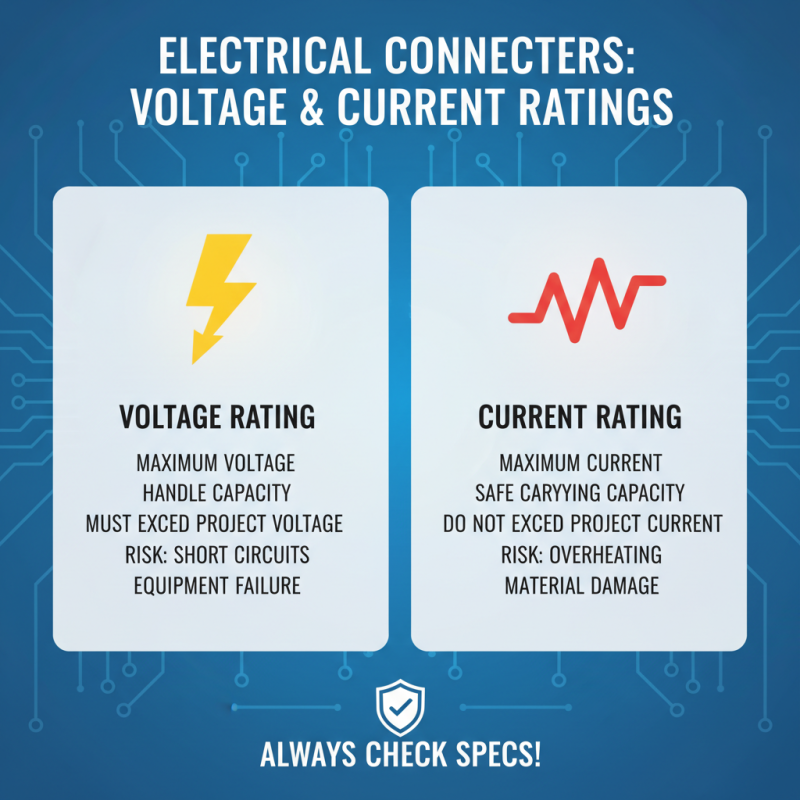

When choosing electrical connectors, voltage and current ratings are crucial. Voltage ratings indicate the maximum voltage a connector can handle. It is vital to ensure this rating exceeds the voltage in your project. If not, you risk short circuits or failures. Current ratings show how much current a connector can safely carry. Exceeding this can lead to overheating. Always check these specifications before making a decision.

Temperature limits are often overlooked but they matter. Connectors should operate within specified temperatures to perform reliably. Extreme temperatures can cause physical changes or material degradation. This leads to poor connections over time. A connector rated for high temperatures can be essential in outdoor or industrial environments. In contrast, a low-temperature-rated connector may be suitable for indoor use.

Evaluating these factors requires attention to detail. You might think you checked everything, but small miscalculations can have big consequences. Always re-evaluate your choices. Are you selecting connectors solely based on appearance? Take time to consider performance specifications. A mismatch could lead to project delays. Remember, a thorough evaluation early on saves time later.

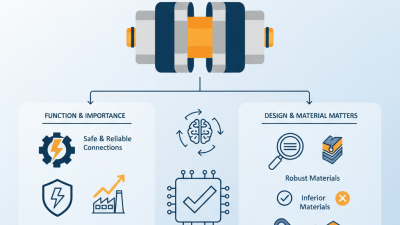

When selecting electrical connectors, the materials and durability are crucial. The right material can enhance performance significantly. Common materials include plastic, metal, and rubber. Each offers different levels of strength and resistance to environmental factors.

Choosing the right connector involves considering the project's demands. For outdoor use, look for weather-resistant materials. In high-heat areas, opt for heat-resistant options. Durability prevents failures over time. Friction and wear can degrade connectors quickly, so select durable alternatives.

**Tips:** Always assess the environment. Think about moisture and temperature. Sometimes, connectors look sturdy but fail in challenging settings. Evaluate before purchasing. Try to visualize the connector's role: it should provide a reliable pathway for electrical flow without interruption. A smart choice today saves time and cost tomorrow. Don’t overlook small details; they matter.

When selecting electrical connectors, industry standards and certifications play a crucial role. Compliance ensures that the connectors can operate safely and effectively. Different industries have unique requirements. For example, aerospace connectors must withstand extreme conditions, while automotive connectors need to handle vibrations. Knowing the right standards helps eliminate guesswork.

However, understanding these standards can be overwhelming. Certification types vary, and some may be more relevant than others. It’s essential to research the specific certifications applicable to your project. Ignoring this step could lead to using subpar connectors. Sometimes, what seems suitable at first may not withstand real-world conditions.

Factors like temperature ratings and moisture resistance are critical. These details often define the longevity of connectors. Review test reports and certifications closely. A connector meeting all specifications may still fail if it lacks proper testing. Not all products will meet your expectations. Reflection on these choices can guide better decisions in the future. Balancing cost with quality is another challenge. Sometimes, the cheapest option can result in greater costs later due to failures.