-

Home

-

About Us

-

Products

-

News

-

Application

-

Service

-

Blog

-

Contact Us

Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

-

Whatsapp

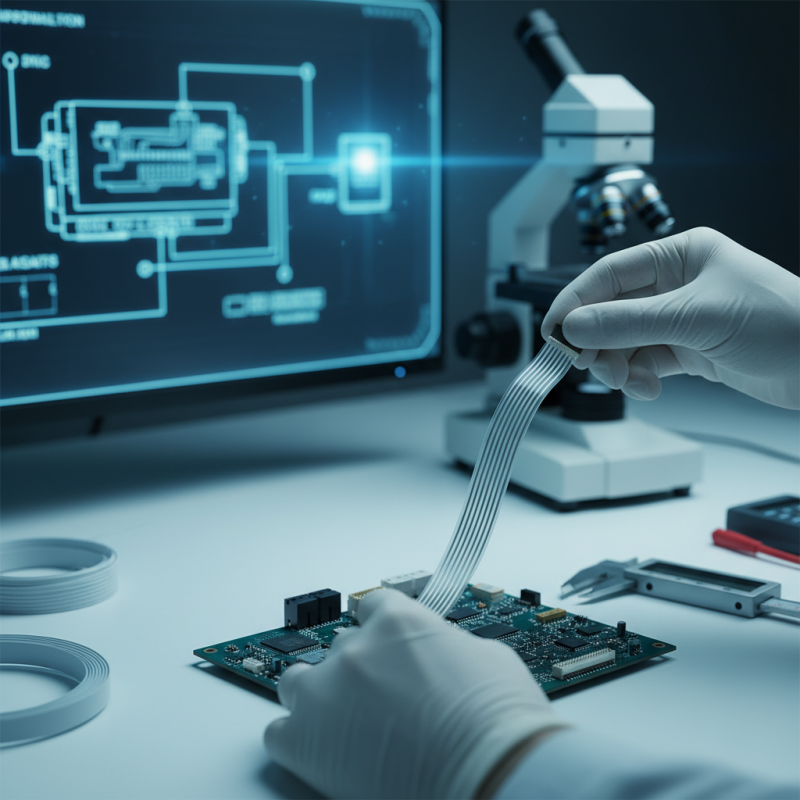

Flexible Flat Cables (FFC) are essential in modern electronics, offering space-saving solutions. According to a recent industry report by MarketsandMarkets, the FFC market is projected to reach $1.5 billion by 2025, driven by innovations in consumer electronics and automotive applications. However, choosing the right FFC for your project can be challenging.

Dr. Emily Carter, an expert in flexible circuit technology, states, "Understanding the specifications of Flexible Flat Cables is crucial for optimal performance." This highlights the importance of not just selecting any FFC but rather one that fits the specific needs of your application. There are many factors to consider, such as thickness, width, and conductor materials.

Mistakes can be costly. Selecting an unsuitable FFC might lead to connectivity issues or increased manufacturing costs. Thus, knowing the nuances of FFC specifications ensures reliability and efficiency in your project. The right FFC can significantly enhance your device's performance, making informed choices vital for success.

Flexible flat cables (FFC) are essential in many electronic projects. They offer unique advantages in tight spaces and complex layouts. Understanding their composition is crucial for selecting the right type for your needs. Most FFCs consist of multiple thin conductors laminated together, ensuring flexibility and ease of routing. This design is beneficial for applications requiring compact wiring solutions.

When choosing an FFC, consider several factors. The number of conductors is vital. More conductors may provide better performance but can lead to increased cost and complexity. Pay attention to the cable’s pitch, which is the distance between conductors. Smaller pitches allow for denser designs but can be challenging to manage. Quality is another aspect to assess. Not all FFCs are created equal, and it’s wise to expect variations in durability and conductivity.

It's important to recognize that not every FFC will suit all applications. Mistakes can occur, such as opting for a cable with insufficient insulation or flexibility. This can lead to complications, especially in high-movement settings. Realizing these potential pitfalls encourages a more measured approach to selection. Designing with FFCs requires careful thought and reflection on the specific needs of your project.

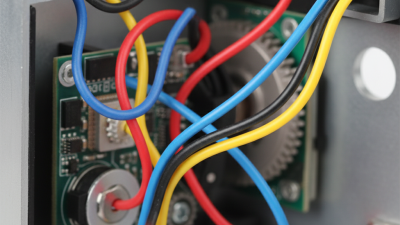

When selecting a flexible flat cable for your project, several key specifications must be prioritized. Pay attention to the cable’s conductor material, as copper offers excellent conductivity. Aluminum is lighter but may not conduct as well. Consider the gauge of the cable; thinner cables are more flexible but handle less current. The right gauge is crucial for safety and performance.

Another significant aspect is the insulation type. PVC is common and cost-effective, while Teflon can withstand higher temperatures. It’s essential to match the insulation with your project requirements. Also, evaluate the cable's bend radius. A smaller bend radius allows for tighter installations but may affect durability.

Take the time to review your project's specific needs. Sketch out your layout to visualize the cable paths. Test various cable types if possible. A mismatch could lead to overheating or signal loss. Analyze your choices carefully and reflect on their long-term implications. Making the right decision in this early stage could save you from costly mistakes down the line.

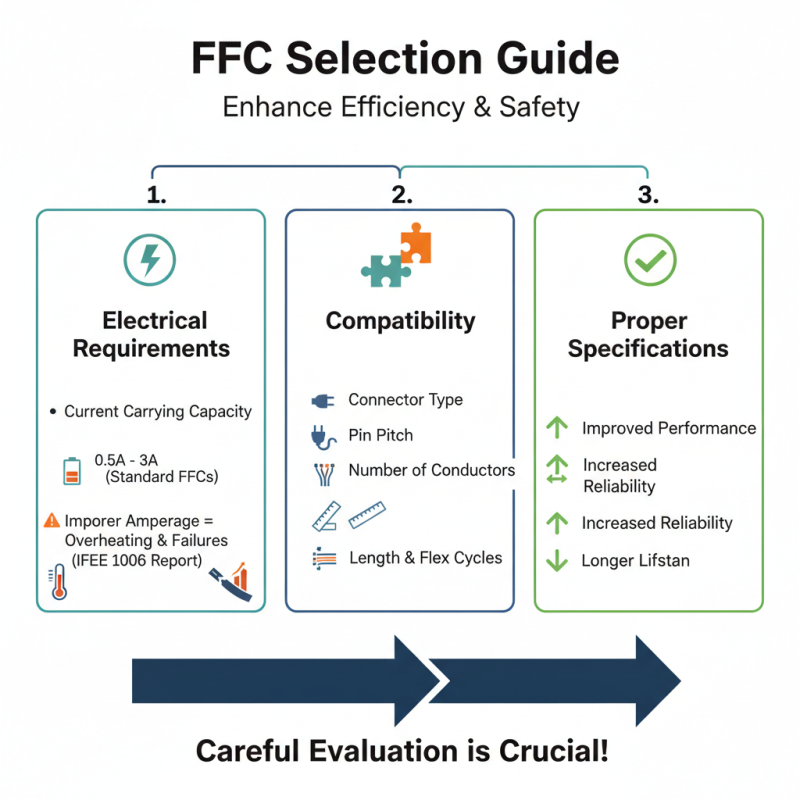

Choosing the right flexible flat cable (FFC) requires careful evaluation of electrical requirements and compatibility. Proper specifications can enhance efficiency and safety. It’s essential to consider current carrying capacity, which typically ranges from 0.5 A to 3 A for most standard FFCs. According to the IEEE 1006 report, improper amperage can lead to overheating and failures.

Insulation type is another critical factor. Polyimide, for example, provides excellent heat resistance, while PVC is more affordable. Each material has its trade-offs. The dielectric strength, usually measured in volts per millimeter, significantly influences performance. For example, cables with a dielectric strength of 8 kV withstand high-voltage applications, while others may fail under lower voltage.

Compatibility with connectors is often overlooked. Incorrect pairing can lead to poor performance and signal loss. Data sheets frequently note that FFCs are designed for specific connector types. The failure to match these can cause operational issues, leading to equipment malfunctions. Keeping track of these details can prevent costly mistakes in the long run.

When selecting the right flexible flat cable, the material choices are crucial for both durability and performance. Common materials include PVC, TPE, and polyurethane. PVC offers decent flexibility but is not always the best choice for extreme conditions. TPE is more resilient but may lack durability in some applications. Polyurethane stands out for its robustness and resistance to harsh environments.

Another consideration is the cable's temperature rating. Some materials perform poorly under high heat. In contrast, others can endure extreme cold. Think about where the cable will be used. Will it face moisture or chemicals? Resistance to these elements is essential. Not every material will meet these challenges effectively.

It’s easy to overlook the importance of proper insulation. Poor insulation can lead to performance issues over time. Inadequate protection exposes the cable to damage and reduces longevity. Consider the intended application carefully. Choosing the wrong material can lead to costly setbacks. Balancing flexibility and durability is more complex than it seems.

| Material Type | Conductor Material | Temperature Rating (°C) | Applications | Flexibility Rating |

|---|---|---|---|---|

| PVC | Copper | -20 to 70 | Consumer Electronics | Good |

| TPE | Copper | -40 to 80 | Industrial Equipment | Excellent |

| Silicone | Copper or Aluminum | -60 to 200 | High-Temperature Applications | Very Good |

| ETFE | Copper | -55 to 150 | Aerospace | Good |

| Nylon | Copper | -40 to 85 | Automotive | Fair |

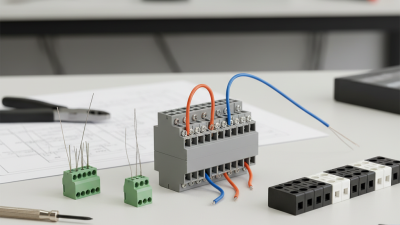

When installing flexible flat cables (FFC), it’s crucial to follow best practices. An environment with high humidity can lead to cable degradation. According to a recent industry report, improperly installed FFCs can fail within months. Proper shielding reduces electromagnetic interference. This is especially vital in sensitive applications like medical devices or data transmission.

Cable routing must be considered carefully. Bending the cables beyond their specified radius risks damage. Regularly inspect the cable paths for any signs of wear. A study showed that 30% of failures stem from mechanical stress or bending issues. Keep connectors clean and securely attached to prevent data loss.

Documentation is key. Always refer to the manufacturer's specifications. Misinterpretation can lead to poor installation practices. One survey indicated that 25% of users faced issues due to lack of proper guidelines. Review the installation regularly and adjust as necessary. It’s essential to reflect on past projects. Learning from mistakes will improve future installations.