-

Home

-

About Us

-

Products

-

News

-

Application

-

Service

-

Blog

-

Contact Us

Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

-

Whatsapp

In the world of electrical projects, choosing the right insulating wires is crucial. The global market for insulating wires is projected to reach $92 billion by 2025, according to a report by Global Industry Analysts. This growth highlights the increasing need for efficient electrical solutions. However, not all insulating wires are created equal. Their diverse materials and properties can make selection challenging.

Experts in the field, such as Dr. Emily Carter, emphasize, "Selecting the right insulating wire can significantly enhance safety and performance." Factors like temperature rating, voltage level, and application type must be considered. Inadequate wire selection can lead to severe consequences, such as electrical failures or fire hazards.

Addressing these challenges requires careful evaluation. Testing insulation resistance and understanding environmental conditions are vital. Missteps in choosing insulating wires can lead not only to project delays but also to increased costs. The road to optimal wire selection is filled with potential pitfalls. Awareness is key to navigating this complex landscape effectively.

When selecting insulating wires, consider the environment. Will they be exposed to heat, moisture, or chemicals? Different materials offer varying degrees of protection in specific conditions. PVC is common, but it may not withstand extreme temperatures. On the other hand, silicone can endure higher heat. Choose wisely based on the project requirements.

Another key factor is the wire’s voltage rating. Ensure the insulation can handle the voltage levels you plan to use. Using a wire with insufficient insulation can lead to breakdowns. This could cause short circuits or even fires. Verify the ratings, and understand a wire's limitations. Testing wires in real conditions can reveal issues that specs might hide.

Don’t forget flexibility and ease of installation. Some wires are stiffer and harder to manipulate. This can be frustrating during complex installations. You may find yourself wishing you had chosen a more flexible option. Always assess your project needs carefully. Reflect on past experiences to make better choices next time.

This chart illustrates important factors to consider when selecting insulating wires for electrical projects, including temperature rating, voltage rating, thickness, and material type. Proper evaluation of these factors ensures optimal performance and safety in electrical applications.

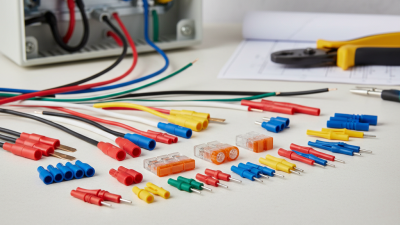

When selecting insulating wires, understanding the insulation materials is crucial. Different materials offer various properties that can significantly affect your project. Common options include PVC, rubber, and Teflon.

PVC is cost-effective and resistant to moisture. It works well for many residential applications. Rubber insulation is flexible and can withstand extreme temperatures. It is ideal for portable equipment. Teflon, on the other hand, excels in high-temperature environments but can be more expensive.

Each material has its drawbacks. PVC can become brittle over time, especially in harsh environments. Rubber may degrade if exposed to oils or chemicals. Teflon, due to its unique properties, may not be necessary for all projects. Careful consideration of the project's specific needs is essential.

It’s essential to reflect on the environment where the wires will be installed. The wrong choice could lead to safety hazards or increased maintenance. Always balance performance with cost to find the best option for your electrical projects.

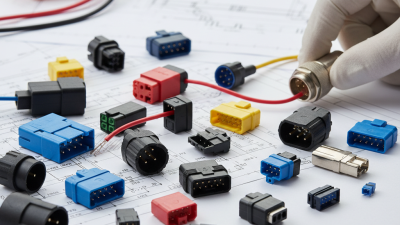

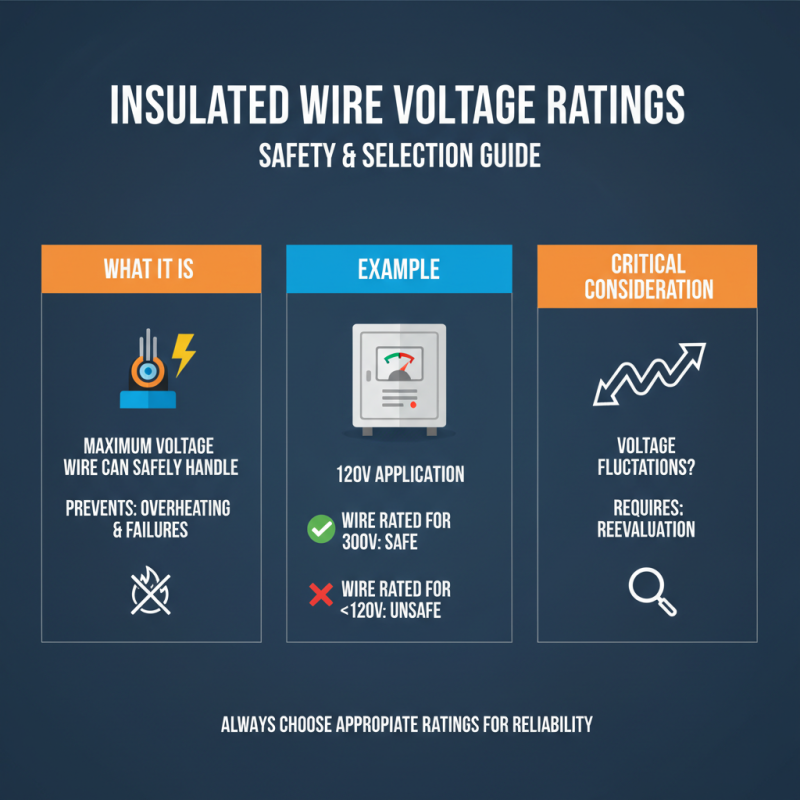

When selecting insulating wires for electrical projects, voltage ratings play a crucial role. These ratings indicate the maximum voltage the wire can safely handle. Choosing wires with appropriate voltage ratings helps to prevent overheating and potential failures. For example, using a wire rated for 300 volts in a 120-volt application is generally safe. However, what if the voltage fluctuates? It may require reevaluation of your choice.

Consider the insulation material as well. Different materials, like PVC or rubber, have varying voltage ratings. They also reflect durability factors. Wires with low-quality insulation might not withstand environmental changes. Factors like temperature and moisture should inform your selection process. You also need to think about wire size. A thicker wire can handle more current but might be more costly or difficult to work with.

Initially, it may seem straightforward. But errors can occur. For instance, misjudging voltage requirements is common. It might not seem significant during a project’s planning stages. Yet, these choices can lead to failures down the line. Always double-check voltage ratings against project needs. Learning from past mistakes helps to make better-informed decisions moving forward.

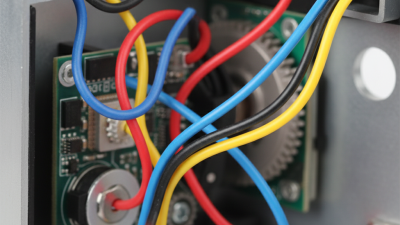

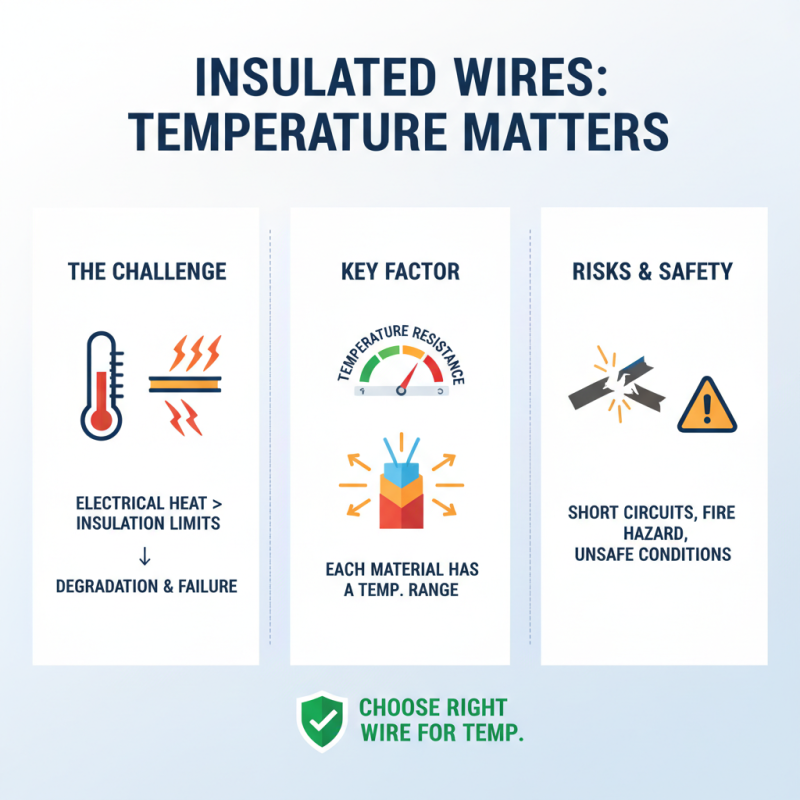

When choosing insulating wires for your electrical projects, temperature resistance stands out as a key factor. Insulation materials are designed to withstand specific temperature ranges. If temperatures exceed these limits, they may degrade. This can lead to failure and unsafe conditions.

For example, PVC insulation is common, but it has a lower temperature tolerance. In high-heat environments, consider silicone or rubber. They can handle higher temperatures effectively. However, these materials may not always be suitable for every application. Each project has unique demands, and wrong choices may lead to performance issues.

Wires in outdoor settings face different challenges. UV exposure can weaken insulation. Internal heat can also affect performance. Evaluating potential temperature levels is crucial. A mismatch may cause shorts or fires. Think about the environment. If unsure, consult with a professional. Taking the time to reflect on these details can save future headaches. Make informed choices to ensure safety and efficiency in your projects.

When selecting insulating wires, it’s essential to consider the specific applications. Different fields require distinct insulation types. For instance, residential wiring demands flexibility and good thermal resistance. In industrial settings, wires must withstand harsh environments. Understanding these needs helps in making a suitable choice.

Tips: Always check the temperature ratings. Some materials degrade under high heat, reducing safety. Pay attention to voltage ratings too. They must align with your project requirements.

Standards play a crucial role in wire selection. Different industries have set guidelines, ensuring safety and efficiency. The National Electrical Code (NEC) provides a framework for residential wiring. For commercial use, consider IEEE and UL standards. These guidelines help avoid potential hazards.

Tips: Consult local codes before starting. They often reflect the specific needs in your area. Testing wires before installation can save future headaches too. Choose wisely; it impacts your project's success.