-

Home

-

About Us

-

Products

-

News

-

Application

-

Service

-

Blog

-

Contact Us

Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

-

Whatsapp

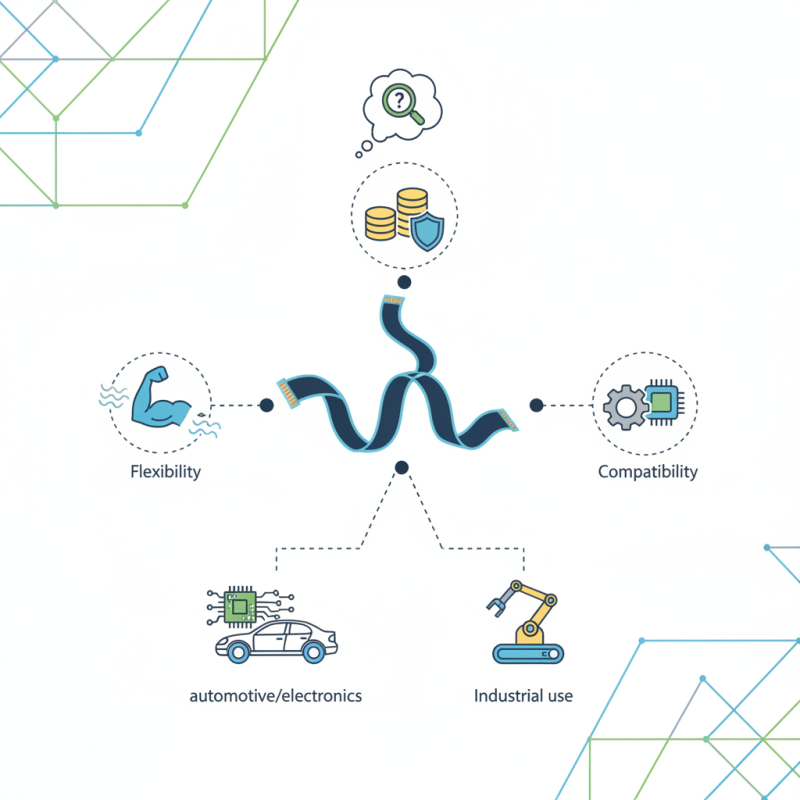

Choosing the right Flat Cable can significantly impact your project. It is crucial to understand your specific requirements. Different flat cables serve various purposes, from powering devices to data transmission.

When considering options, think about flexibility, thickness, and durability. Flat cables come in multiple designs, including ribbon and flexible variants. Each design caters to unique applications, such as electronics, automotive, or industrial use. Limited knowledge might lead to poor selection. This can hinder performance and increase costs.

Reflection is essential when evaluating your needs. Ask yourself what type of Flat Cable aligns with your project goals. Don’t overlook the importance of compatibility and ease of installation. Explore various options and weigh their pros and cons. Each choice you make will play a role in your project’s success.

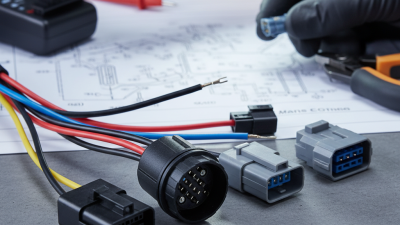

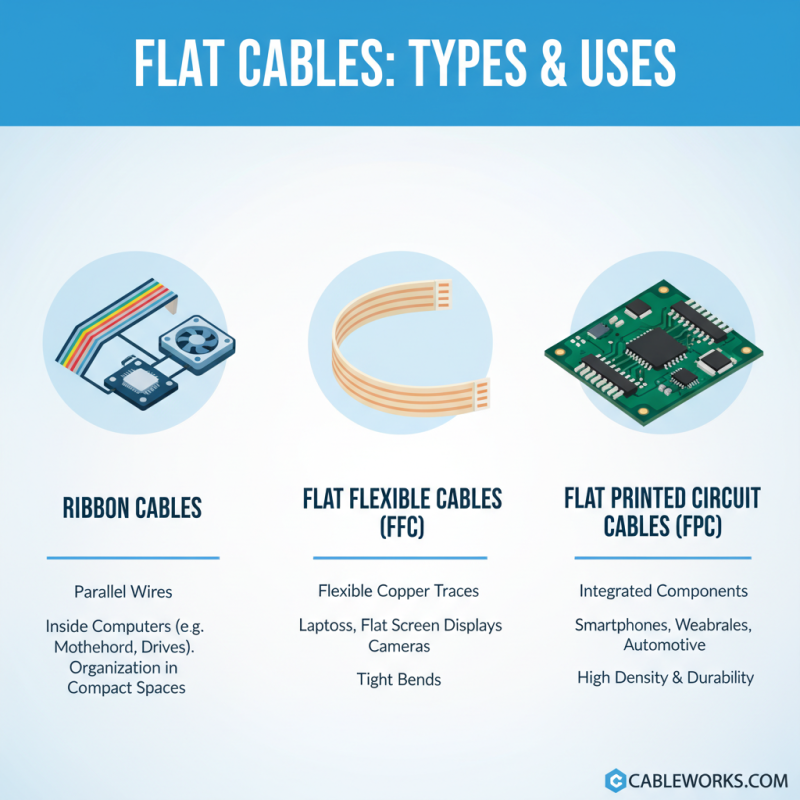

Flat cables come in various types, each serving a unique purpose. The most common types include ribbon cables, flat flexible cables (FFC), and flat printed circuit cables (FPC). Ribbon cables are often found inside computers, connecting various components. They have multiple parallel wires, making them easy to identify. These cables help maintain organization, which is essential in compact spaces.

FFC cables are thinner and more flexible than ribbon cables. They are employed in applications where space is a constraint. Their design allows for tight bends, making them excellent for portable devices. However, selecting the right gauge can be tricky. A thicker cable may be more durable but less flexible. A thinner one may bend easily but can break faster under stress.

FPC cables are similar but are often used for specialized applications like cameras or smartphones. They may offer advantages, such as better heat resistance. Yet, they can also be more expensive. You might find yourself wondering: is the additional cost worth the performance? Each type has trade-offs, and your choice should align with your specific needs. Think about the balance between durability and flexibility. Your decision could impact performance significantly.

Choosing the right flat cable involves several key specifications. You need to consider the wire gauge. A lower gauge number means a thicker wire, which can carry more current. Check the insulation type as well. Different materials have varying heat and abrasion resistance.

Pay attention to the cable length too. A longer cable can incur more resistance, potentially affecting performance. Look at the temperature rating. This ensures the cable can handle the conditions it will be in.

Remember, selecting the right flat cable is not always straightforward. Sometimes, cables can appear perfect at first glance but fail under stress. Testing under actual conditions can reveal flaws. Verify compatibility with your devices. It’s a common oversight. Users often assume all cables will work seamlessly across different applications. Such assumptions can lead to disappointing results.

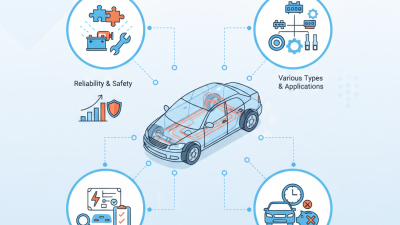

When selecting a flat cable, it’s crucial to identify your specific application requirements. Understanding the environment where the cable will be used impacts its durability. For instance, is it for indoor use or exposed to harsh conditions? Consider temperature ranges and moisture levels. A cable intended for outdoor use must withstand UV rays and water exposure.

Next, think about the electrical specifications. This includes current capacity and voltage rating. If the cable will handle high currents, ensure it has the proper gauge. Pay attention to data transfer needs as well. Some applications demand high-speed transmission, while others may not. Ask yourself these questions: Will it be used for audio, video, or power? Choosing incorrectly could lead to inefficiency.

Lastly, consider physical characteristics. Length and flexibility should match your requirements. A rigid cable may be unsuitable for tight spaces. Remember, improper choices can lead to performance issues. Don't overlook the importance of insulation material. It can affect signal integrity and safety. Explore your needs thoroughly, and don’t rush the decision. Each requirement shapes the overall effectiveness of your cable system.

This bar chart illustrates key specifications for selecting the best flat cable, including bandwidth, flexibility, durability, price, and weight. These factors are crucial to identify the right flat cable for your specific application requirements.

When selecting a flat cable, durability is a key factor. It determines how well a cable can withstand wear and tear over time. Look for materials that resist fraying and cracking. A durable cable can endure bends without breaking. Different environments may require different levels of durability. For instance, cables used in tight spaces may need extra protection.

Flexibility is equally important. A flexible cable can be routed in various directions easily. This is especially useful in tight corners or cramped spaces. However, more flexible cables may be less durable. Finding the right balance is crucial. Sometimes, choosing a cable that is too flexible can lead to issues. Consider your specific needs carefully.

Understanding these traits is essential. Selecting the wrong cable can lead to frayed connections and costly replacements. Pay attention to how cables perform under pressure. Reviews and real-world tests can provide valuable insight. A well-chosen cable can improve your setup significantly. Being mindful during the selection process will save you frustration down the line.

| Cable Type | Durability Rating | Flexibility Rating | Applications |

|---|---|---|---|

| Flat PVC Cable | Moderate | High | Household, Light Duty |

| Flat Silicone Cable | High | Excellent | Flexible Applications, Automotive |

| Flat TPE Cable | Very High | High | Industrial, Outdoor Use |

| Flat ELT Cable | Moderate | Moderate | Low Voltage Applications |

| Flat Data Transfer Cable | High | Excellent | Networking, Data Communication |

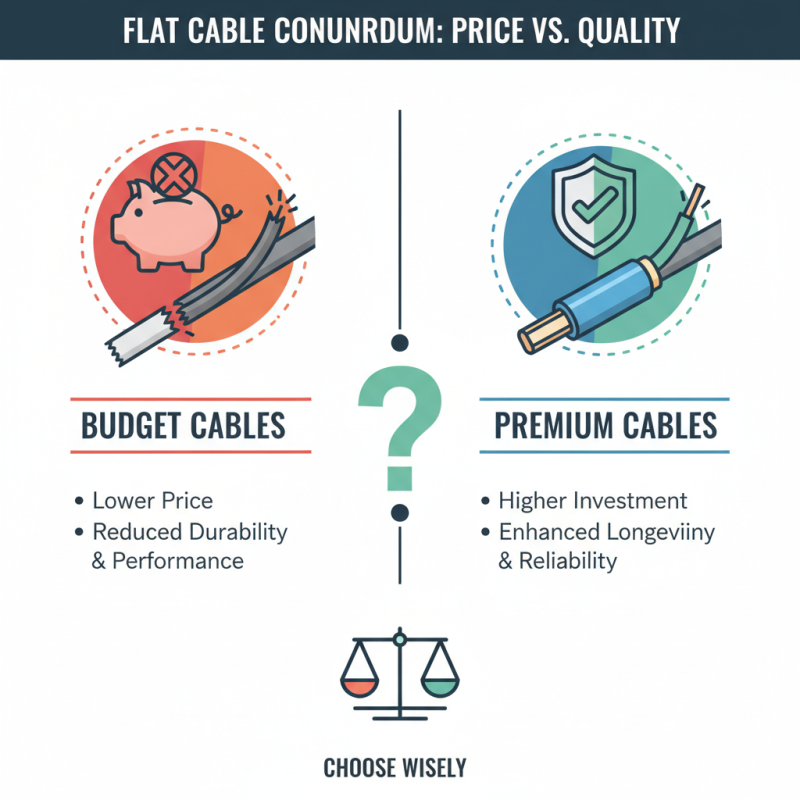

Choosing the right flat cable can be challenging. The market is flooded with options, and each has its pros and cons. Cost and quality often go hand in hand, but this isn't always the case. It's essential to evaluate what aspects matter most to you. Price can be appealing, but lower costs often mean sacrificing durability or performance.

When assessing quality, consider the materials used in the cable. Some cables may look appealing but use inferior components. They might fail sooner than expected. Read reviews, and gather information from users. It helps to know about real-life experiences. However, remember that everyone has different needs. What works for one person may not work for you.

Think about your specific requirements. Will the cable be exposed to harsh conditions? If yes, prioritize quality over cost. Sometimes, it’s worth spending a bit more to ensure longevity. On the other hand, a simple application might not require the highest quality. The balance between cost and quality is subjective. Reflect on your situation before making a decision.