-

Home

-

About Us

-

Products

-

News

-

Application

-

Service

-

Blog

-

Contact Us

Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

-

Whatsapp

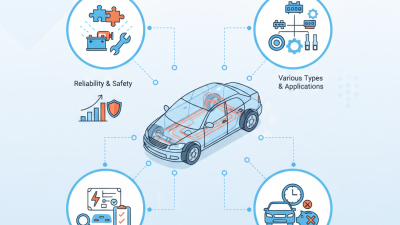

Choosing the right auto connectors for your vehicle is crucial. In the automotive industry, data shows that poor connector choices can lead to performance issues. A report from the Society of Automotive Engineers reveals that 30% of automotive electrical failures are linked to connector problems.

Auto connectors play a vital role in the vehicle’s electrical systems. They ensure seamless communication between various components. A reliable connector can prevent costly repairs. However, selecting the wrong type can create compatibility issues. Efficiency, durability, and temperature resistance are key factors to consider when making this choice.

Reflecting on your needs is essential. With numerous options available, it can be overwhelming. Understanding specific requirements can lead to better decisions. Not all auto connectors are created equal; some may not meet your expectations. Carefully evaluating your vehicle's specifications is critical for optimal functionality.

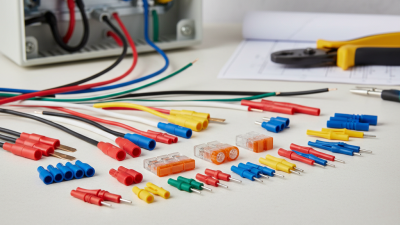

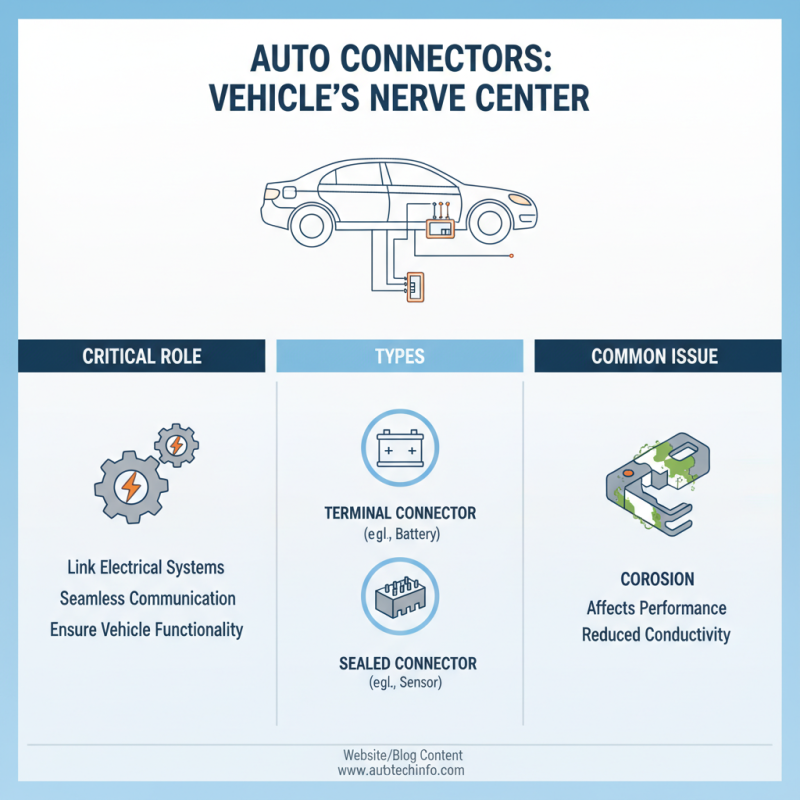

Auto connectors play a critical role in vehicle functionality. They link various electrical systems, ensuring seamless communication within the vehicle. There are several types of connectors, each serving a specific purpose. For instance, a terminal connector is commonly used for battery connections. This type often faces issues like corrosion, which can affect vehicle performance.

Another type is the circular connector, which provides a secure connection for sensors. These connectors are robust but may require regular checks for wear and tear. Repairs can be challenging, as specialized tools are often needed. Similarly, automotive Ethernet connectors are crucial for modern vehicles that rely on data transfer. However, their complex design can lead to misalignment during installation.

It is essential to reflect on your vehicle's specific needs when choosing connectors. Compatibility is key. It can be frustrating to purchase the wrong type, resulting in technical issues. Make a checklist of your vehicle's components and how they connect. This process helps ensure you select the right type of auto connector.

Choosing the right auto connectors for your vehicle is crucial. The right connectors ensure reliable electrical connections, affecting safety and performance. Industry reports indicate that improper connector selection can lead to a 15% increase in vehicle malfunction rates. This emphasizes the importance of understanding specific needs.

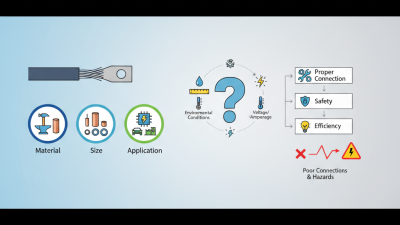

One key factor is the connector's material. Different materials have varying levels of conductivity and corrosion resistance. For instance, copper connectors often excel in performance but may corrode faster than other options. It’s vital to consider the environment where the connector will be used. High humidity and exposure to chemicals can compromise integrity.

Tip: Always inspect the connector's insulation. Poor insulation can lead to short circuits.

Another consideration is the connector type. Depending on your vehicle's electrical system, you may need weatherproof connectors or standard types. Reports highlight that weatherproof connectors can reduce failure rates significantly.

Tip: Measure the connector size accurately. Mismatched sizes can create loose connections or be too tight, damaging components.

Being aware of these factors can enhance your vehicle's reliability. However, sometimes, even the best selection may not perform as expected. Regular maintenance is necessary to ensure optimal functioning. Reassessing your choices periodically is a wise approach.

| Connector Type | Material | Current Rating (A) | Operating Temperature (°C) | IP Rating | Typical Applications |

|---|---|---|---|---|---|

| Blade Connector | Copper Alloy | 15 | -40 to 125 | IP67 | Lighting, Dashboard |

| Round Connector | Plastic/Aluminum | 20 | -30 to 85 | IP68 | Audio Systems, Sensors |

| DT Connector | Nylon | 30 | -55 to 125 | IP67 | Power Distribution, Motors |

| Mini Connector | Copper | 10 | -40 to 105 | IP66 | Data Transfer, Small Devices |

| Terminal Block | Thermoplastic | 40 | -25 to 85 | IP50 | Control systems, Power Supply |

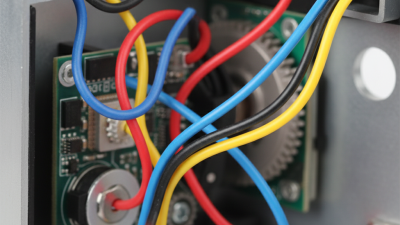

When selecting auto connectors, compatibility is key. Not all connectors fit every vehicle. Ensure that the specifications meet your vehicle’s requirements. Check the dimensions, pin configurations, and materials used. An incompatible connector can lead to malfunction and potentially costly repairs.

Tips: Always consult your vehicle’s manual. It contains crucial details about the types of connectors needed. Don’t skip this step. You might think you know, but small differences can cause issues. Verify that the connectors can handle your vehicle’s electrical demand.

Incompatible connectors may look similar, yet they can perform poorly. Reflect on this: mismatched connectors could lead to shorts or other failures. Also, consider the weather conditions in your area. Connectors should be rugged and weather-resistant. An overlooked detail could lead to bigger problems down the road.

When selecting auto connectors, material composition plays a crucial role in durability. Metal connectors, particularly those made of copper alloys, offer excellent conductivity. According to industry reports, copper connectors can reduce resistance by up to 30%. This ensures better performance and longevity in high-current applications. However, they are prone to corrosion if not properly shielded.

Plastic housing materials also matter. Thermoplastic elastomers (TPE) are gaining popularity due to their balanced heat resistance and flexibility. TPE can withstand temperatures from -20°C to 120°C, making them suitable for various weather conditions. On the other hand, some cheap plastics deteriorate quickly, risking connector failure over time.

Tips: Always check for certifications like ISO and SAE. They indicate that the material has been tested for quality. Inspect hardness and flexibility metrics as well. A connector should not easily bend or break under moderate stress. Keep in mind that many connectors may look similar but differ significantly in performance. So, invest time in understanding these differences for the best outcome.

Choosing the right auto connectors can feel overwhelming. Safety is a top priority in the automotive industry. Therefore, understanding safety standards and certifications is crucial. Automotive connectors must withstand harsh conditions. High temperatures, vibrations, and moisture can degrade performance.

Look for connectors that meet industry safety standards. These may include ISO, DIN, or SAE certifications. Complying with these standards ensures reliability in critical situations. Not all connectors are created equal. Some may not perform well under specific conditions. Research the connectors thoroughly before making a choice.

It’s easy to overlook the importance of certifications. Investing in cheap alternatives might save money but lead to failures. Failed connectors can cause serious issues. These could range from minor inconvenience to significant hazards. Always prioritize quality over cost when selecting auto connectors. Don’t be afraid to ask questions. Seek advice from experts if you feel uncertain.