-

Home

-

About Us

-

Products

-

News

-

Application

-

Service

-

Blog

-

Contact Us

Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

-

Whatsapp

In today's fast-paced electronics sector, the importance of the Ffc Connector cannot be overstated. According to a recent report by ResearchAndMarkets, the global flat flex cable market is projected to reach $4.2 billion by 2026, largely driven by the increasing adoption of Ffc Connectors in consumer electronics. These connectors are pivotal in ensuring compact design and efficient connectivity.

Expert Linda Thompson, a leading figure in the connector industry, states, "Ffc connectors are revolutionizing the way devices connect, allowing for thinner and lighter designs." Her insights reflect the growing trend toward miniaturization in technology. However, there remain critical challenges in ensuring reliability and performance under various conditions.

Despite the advancements, the production and implementation of Ffc Connectors can occasionally lead to performance issues. Manufacturers must continuously innovate to address these shortcomings while maintaining quality standards. The industry must reflect on these challenges to enhance the reliability of Ffc Connectors, ensuring they meet the demands of modern electronics.

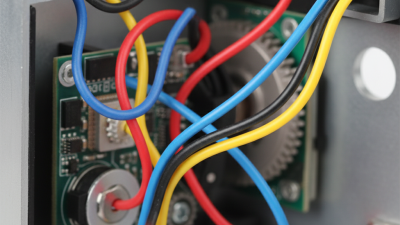

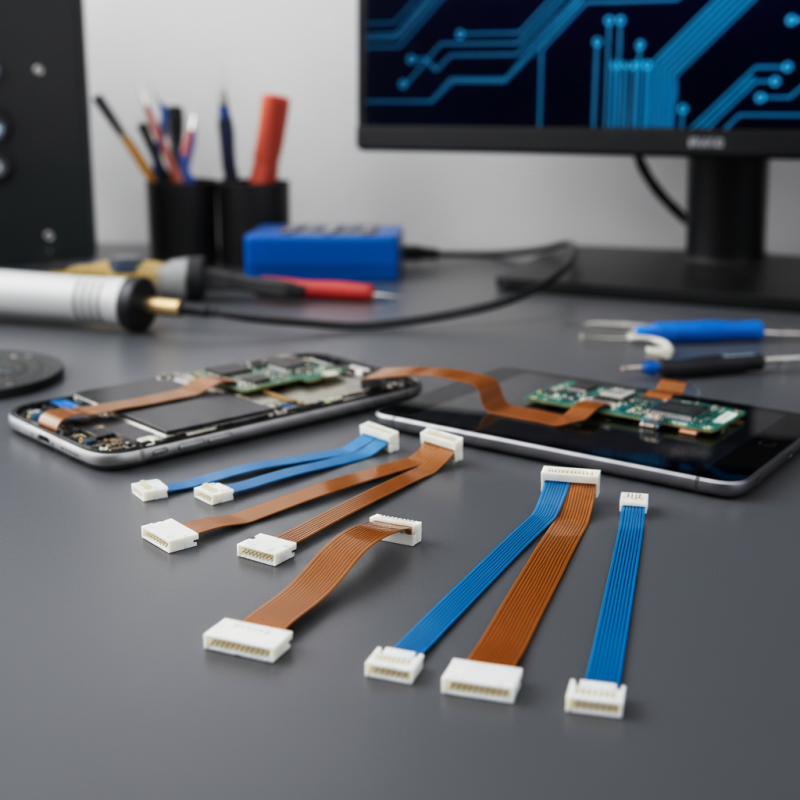

FFC connectors, or Flat Flexible Connectors, play a crucial role in modern electronics. Their design allows for space-saving connections between different components. These connectors are thin and flexible, making them easy to route in compact devices. Many gadgets, including smartphones and laptops, rely on FFC connectors for efficient signal transmission.

The functionality of FFC connectors is impressive. They provide reliable connections while minimizing electromagnetic interference. The flat ribbon design allows multiple connections to be made simultaneously. This feature increases efficiency in space-constrained environments. However, improper handling can lead to failures. It’s essential to ensure proper alignment when connecting them. Users sometimes overlook this step, leading to unnecessary malfunctions.

In practice, FFC connectors can be challenging. Their delicate nature requires care during installation. The flexibility also raises concerns about wear over time. Regular inspection is important to prevent long-term issues. The evolving technology in electronics demands that FFC connectors adapt continuously. Designers must reflect on these challenges to improve their implementations.

| Dimension | Description | Importance |

|---|---|---|

| Pitch | The distance between the center of one pin to the center of the next pin. | Critical for ensuring the right fit and compatibility with various devices. |

| Number of Pins | Refers to the total number of electrical connections within the connector. | Determines the amount of data that can be transmitted simultaneously. |

| Operating Temperature | The temperature range in which the connector can function effectively. | Ensures reliability in various environmental conditions. |

| Materials Used | Commonly made from plastic, copper, and gold-plated contacts. | Affects durability, electrical conductivity, and overall performance. |

| Mounting Type | Can be surface-mounted or through-hole mounted. | Plays a role in the assembly process and space-saving in design. |

FFC connectors play a crucial role in modern electronics. Their design supports compact and flexible connections, making them ideal for various devices. These connectors enhance space efficiency, accommodating the shrinking dimensions of electronic components. For instance, in laptops and smartphones, FFC connectors help streamline internal configurations, offering more room for batteries and screens.

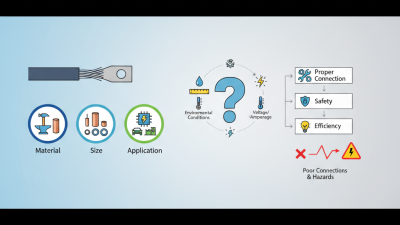

One key advantage of FFC connectors is their ability to handle numerous connections in a single flat cable. This reduces clutter and simplifies assembly. The lightweight nature of these connectors also helps in portable devices where every gram counts. However, challenges remain in terms of compatibility. Not every connector will fit every device. Carefully considering specifications is essential for successful implementation. In some cases, using the wrong connector can lead to unreliable performance, requiring a reevaluation of design choices.

Moreover, FFC connectors improve signal integrity. They minimize the risk of electromagnetic interference. This is especially important in high-speed applications. Nevertheless, over time, connectors can face wear and tear, impacting performance. Regular testing and updates are necessary to maintain efficiency. Engaging in such reflective practices can lead to better design decisions in future projects.

FFC connectors are pivotal in various electronic industries. They offer compact designs and efficient data transmission. These connectors are widely used in consumer electronics like smartphones and laptops. In fact, the global flexible flat cable market is projected to reach $19.98 billion by 2026, driven mainly by increased demand in the consumer electronics sector.

In automotive electronics, FFC connectors enable advanced features like infotainment systems and navigation tools. According to a market report, the automotive electronics market is expected to grow at a CAGR of 7.5% between 2021 and 2026. This growth emphasizes the need for reliable connectors that can withstand harsh conditions. However, the challenge lies in maintaining quality standards while reducing costs.

Industrial automation also benefits from FFC connectors. They facilitate connections in robotic systems and assembly lines. The global industrial automation market is projected to surpass $200 billion by 2026. Yet, the reliance on FFC connectors raises concerns about long-term durability and performance. Finding the balance between innovation and reliability is crucial in this fast-paced sector.

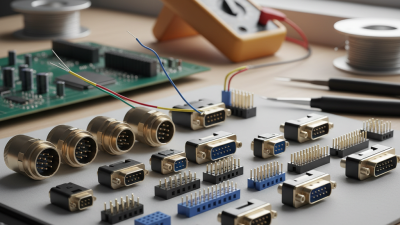

FFC connectors, or flat flexible connectors, have become increasingly popular in modern electronic devices. Their design allows for thin profiles, making them ideal for compact spaces. FFC connectors can save space in smartphones, laptops, and other gadgets where every millimeter counts. In contrast, traditional connectors, like cylindrical or rectangular types, often require more room due to their bulkier design.

When comparing FFC connectors to other connector types, it’s clear that each has its strengths. For example, while FFC connectors are flexible and easy to route, they might not provide the same durability as heavy-duty connectors. Similarly, rectangular connectors can offer better stability in harsh environments but do not have the same space-saving advantage. The choice often depends on the specific application and environment where the connector will be used.

In essence, the performance of FFC connectors lies in their simplicity and form factor. Yet, they can be more susceptible to mechanical stress. This raises questions about longevity in certain applications. Engineers must weigh the pros and cons of each type carefully. It’s a balancing act between size, flexibility, and durability. Making the right choice requires a nuanced understanding of each connector’s impact in the design.

The evolution of FFC connector technology reflects the rapid advancements in modern electronics. These connectors are increasingly being utilized in various applications, from consumer gadgets to medical devices. The trend towards miniaturization is driving the demand for smaller, lighter, yet efficient connectors. As devices shrink, FFC connectors must maintain performance without compromising reliability.

Future innovations could entail enhanced materials that improve durability and flexibility. For instance, some manufacturers are exploring conductive polymers for their resilience. This could potentially reduce the space they occupy while maintaining or even enhancing conductivity. However, questions remain about the long-term stability of these materials under extreme conditions. There’s still much to learn.

The push towards sustainable manufacturing processes is another exciting trend. In the quest for greener electronics, recycling and biodegradable materials are under consideration. This shift presents challenges in balancing performance and environmental responsibility. As we look ahead, designers must grapple with these complexities. The journey of FFC connectors is still unfolding, opening doors for creativity and critical thinking in the electronics sector.

This chart illustrates the growth of FFC connector usage in the electronics industry from 2015 to 2023. The increasing demand reflects advancements in technology and the role of FFC connectors in modern devices, highlighting their essential nature in contemporary electronics design.