-

Home

-

About Us

-

Products

-

News

-

Application

-

Service

-

Blog

-

Contact Us

Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

-

Whatsapp

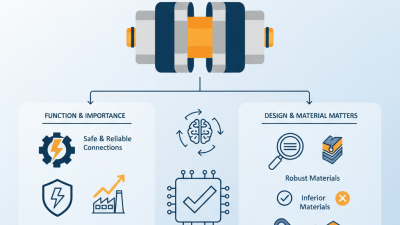

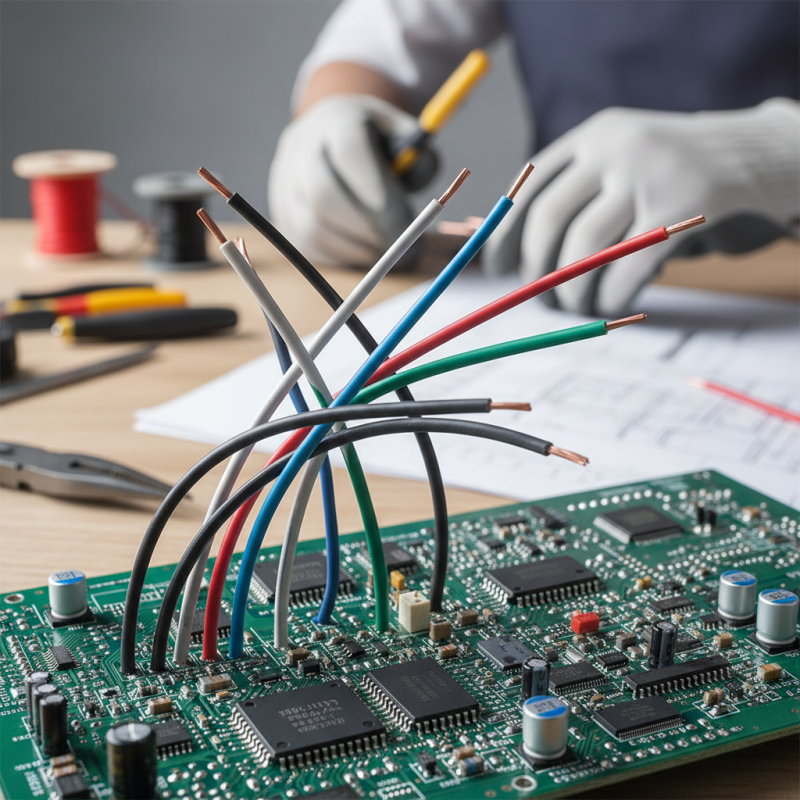

Board Wire plays a pivotal role in various electrical projects. According to industry studies, 80% of electrical installations require high-quality wiring. This emphasizes the crucial need for reliable materials, particularly board wire, in ensuring safety and efficiency. Board wire is specifically designed to withstand heat and stress, making it a wise choice for diverse applications.

In recent years, reports indicate a 20% increase in electrical project demands. As projects grow in scale, the need for robust wiring solutions like board wire becomes evident. Many professionals recognize that lower quality wires can lead to failures and hazards. In fact, nearly 30% of electrical failures trace back to inadequate wiring choices. The correlation between quality installation and long-term reliability highlights the importance of selecting the right materials.

Despite the advantages, some may overlook board wire's significance due to perceived costs. However, investing in quality wiring can prevent costly repairs and enhance safety. The challenge lies in balancing budget constraints with the need for quality. Board wire isn't just an option; it’s essential for the integrity of electrical systems. Understanding its importance can lead to more informed decisions in electrical projects.

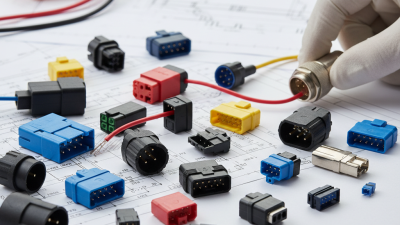

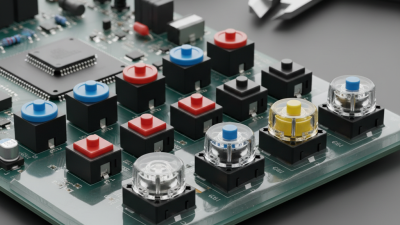

Board wire is a type of electrical wire commonly used in various electrical projects. This wire typically carries current and connects different components in circuits. Board wire consists of thin strands of copper, often with insulating materials. The insulation protects users from electric shock and prevents short circuits.

In practice, board wire is essential for both simple and complex applications. Hobbyists often use this wire in DIY electronics, such as model circuits. Its flexibility makes it easy to work with. Professionals also rely on board wire for installations in homes and industrial settings. It allows for secure and efficient connections.

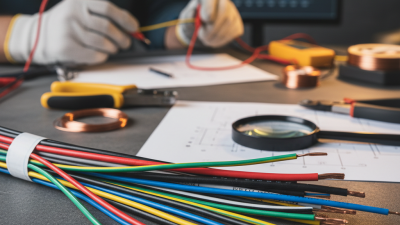

However, working with board wire can present challenges. Proper stripping and soldering techniques are critical for safety and functionality. Mistakes can lead to malfunction or hazards. Many beginners may overlook this importance, leading to frustrating results. Understanding the intricacies of board wire is crucial for success in electrical projects.

Board wire plays a crucial role in electrical projects. Its flexibility and durability make it a preferred choice among electricians. High-quality board wire can handle temperatures up to 90 degrees Celsius, according to industry standards. This heat resistance is critical in ensuring safety and efficiency in wiring designs.

One key advantage of using board wire is its ease of installation. Lightweight and manageable, board wire simplifies the wiring process. Reports indicate that using board wire can reduce installation time by up to 30%. This efficiency not only saves labor costs but also minimizes downtime. Additionally, board wire is less prone to fraying and breakage compared to other types of wiring.

However, not all board wires are created equal. Variations in quality can affect performance. Selecting the right gauge is essential, as using a wire that’s too thin may lead to overheating. This could pose risks of electrical fires. Construction professionals must continuously educate themselves on the changing standards and technologies in wire manufacturing to make informed choices.

Board wire has numerous applications across various industries. It is widely used in automation systems, wiring harnesses, and control panels. In the automotive sector, board wire plays a crucial role in connecting electrical components. It ensures that systems function smoothly, making it essential for vehicle performance. The flexibility and durability of board wire make it a preferred choice in these settings.

In the telecommunications industry, board wire is vital for transmitting signals. It connects equipment, allowing for efficient communication. Many facilities rely on board wire to maintain network integrity. The choice of material can affect signal quality, so careful consideration is needed.

Tips: Always check the wire gauge for your specific application. Thicker wires can carry more current but may be less flexible. Additionally, consider temperature ratings to ensure safety. Pay attention to insulation types as they affect durability and performance.

Selecting the right board wire is crucial for any electrical project. Several factors must be considered. One major aspect is the gauge of the wire. Thicker wires can carry more current but are also less flexible. This might impact your project, especially in tight spaces.

Another important factor is insulation type. Various materials offer different levels of protection. For instance, some insulations handle high temperatures better. If your project involves heat, this detail can make or break your success. Think carefully about the environment the wire will be exposed to.

It's also vital to assess the wire's length requirements. Longer wires can lead to voltage drops, affecting performance. Check for installations that require longer runs. Additionally, think about the aesthetics of your project. Wire colors and styles can influence how the final product looks. Sometimes, the ideal choice might not be the most obvious one. Balancing functionality and aesthetics takes careful thought.

Board wire is a core component in many electrical systems. Its flexibility and durability make it ideal for various projects. However, proper maintenance and safety are crucial to ensure its effectiveness.

Regular inspection of board wire is essential. Look for frays or signs of wear. Any damage can lead to short circuits. Replacing damaged wires immediately is a must. Use a multimeter to check for continuity. This tool can help identify hidden issues. Always wear gloves when handling electrical components. Safety should come first.

When installing board wire, keep connections tight and secure. Loose connections can cause overheating. Ensure proper insulation is in place. Over time, wires can degrade. Always check that the insulation has not cracked or split. Use cable ties for organization. A tidy setup can prevent accidents. Keeping wires neatly arranged might seem trivial, but it significantly reduces hazards.