-

Home

-

About Us

-

Products

-

News

-

Application

-

Service

-

Blog

-

Contact Us

Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

-

Whatsapp

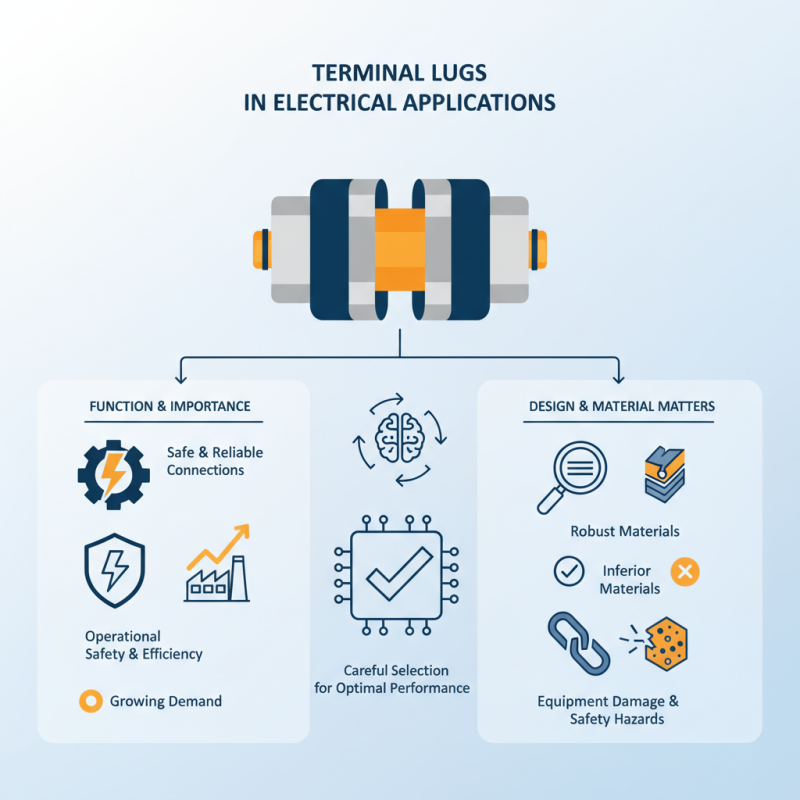

Terminal lugs play a crucial role in electrical applications. These components ensure safe and reliable connections in various systems. According to a recent industry report by the Electrical Connector Research Group, the global market for terminal lugs is projected to grow steadily. This growth reflects the rising demand for robust electrical connections across sectors.

Expert John Smith, a leading figure in the electrical components industry, states, “Terminal lugs are essential for operational safety and efficiency.” This highlights the significance of choosing the right terminal lugs. Inadequate connections can lead to failures, which may result in equipment damage or safety hazards.

Moreover, the design and material of terminal lugs can affect performance. Many manufacturers focus on reliability but overlook potential weaknesses. For instance, using inferior materials can compromise the connection. Therefore, careful consideration in selecting terminal lugs is essential for optimal performance in electrical applications.

Terminal lugs play a crucial role in electrical wiring. They connect wires to various components like batteries, circuit breakers, and distribution boards. Proper connections ensure optimal electrical flow and safety. According to a report by the National Electrical Manufacturers Association (NEMA), more than 30% of electrical failures are due to poor connections.

The design of terminal lugs allows for a secure connection. They come in various shapes and sizes, catering to different wire types. A study from Electrical Industry Association highlights that using the correct lug can increase conductivity by 15%. However, many installers overlook the importance of matching the lug type with wire gauge. This mismatch can lead to overheating or even fire hazards.

It's vital to maintain a proper connection. Using the right tools when crimping lugs is essential. A poorly crimped connection can create resistance. This might seem minor, but resistance can cause significant problems over time. Therefore, training and awareness about proper application are necessary in the electrical field.

Terminal lugs are essential components in electrical systems. They ensure safe and reliable connections between wires and terminals. Understanding different types of terminal lugs is crucial for efficient functioning in various applications.

There are several types of terminal lugs:

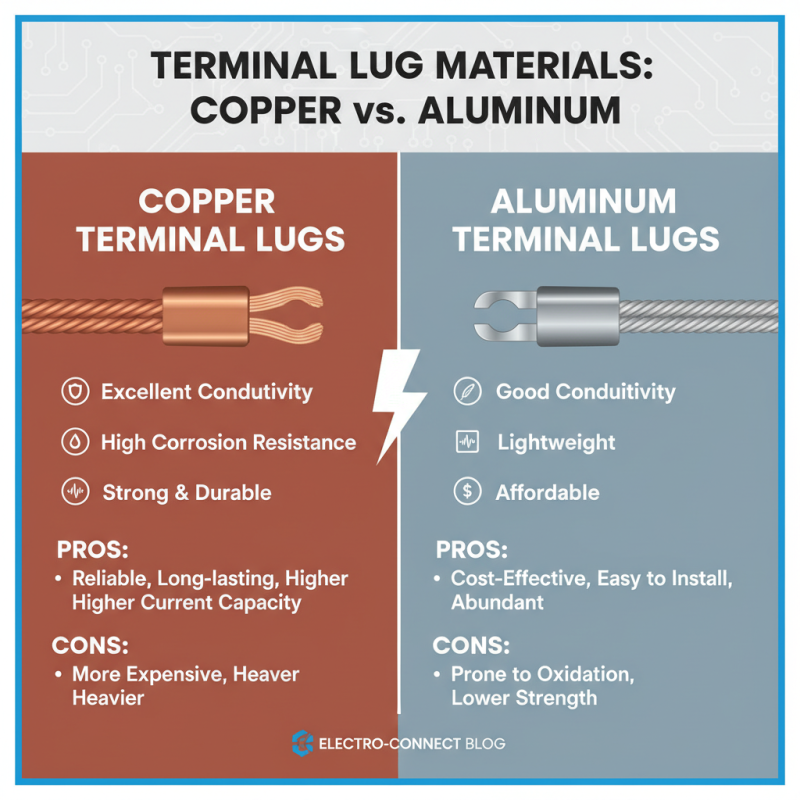

Terminal lugs are essential components in electrical systems. They create a secure connection between wires and electrical equipment. Choosing the right material for these lugs can greatly impact performance. Two common materials are copper and aluminum. Each has its advantages and drawbacks.

Copper terminal lugs are highly conductive. They offer lower electrical resistance compared to aluminum. This means they can handle higher currents without overheating. However, copper is also heavier and more expensive. Installation may require specific tools for crimping. In contrast, aluminum lugs are lighter and more cost-effective. They are easier to handle, especially in large installations. Yet, aluminum can have higher resistance and may require anti-oxidation treatment.

When comparing performance data, thermal conductivity is key. Copper excels in heat dissipation. This can prolong the lifespan of connections. Aluminum lugs can expand and contract more under temperature changes, leading to potential issues. The choice often depends on the application. In high-demand environments, copper might be the safer bet. For budget-friendly projects, aluminum may suffice. It’s crucial to weigh these factors carefully.

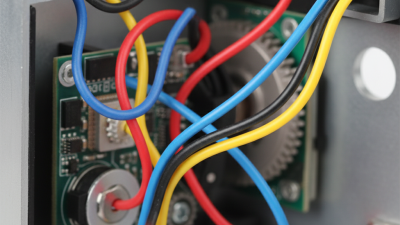

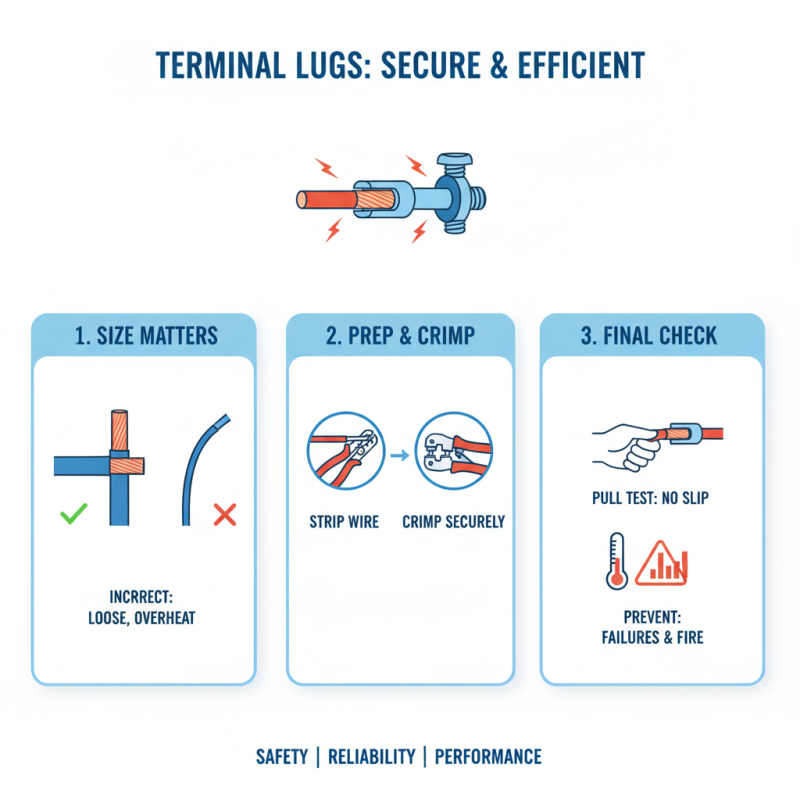

Terminal lugs play a crucial role in electrical connections. Proper installation is key to ensuring both safety and efficiency. Start by selecting the right size lug for your wire gauge. A mismatch can lead to overheating and potential failures.

When crimping, maintain a firm grip. Position the wire fully within the lug for a secure fit. It is essential to check for any exposed wire after crimping. This can prevent short circuits and electrical hazards. Sometimes, people overlook this detail, thinking it’s unimportant. That can lead to serious issues later.

Screw connections should be tightened adequately. Loose connections will increase resistance, leading to wasted energy. Inspect them regularly for oxidation or corrosion. It's easy to forget this step. Regular maintenance helps in prolonging the life of electrical systems. By following these techniques, better connections can be achieved.

Terminal lugs play a crucial role in electrical systems. These components ensure safe and reliable connections for conductors. However, they must comply with strict safety standards. Organizations like the Underwriters Laboratories (UL) and the International Electrotechnical Commission (IEC) publish guidelines. These standards help prevent electrical fires and ensure equipment safety.

Recent reports indicate that improper installation of terminal lugs can lead to significant failures. A study shows that nearly 30% of electrical failures in industrial settings stem from faulty connections. This highlights the importance of adhering to electrical codes and standards. Furthermore, regular inspections are vital. They help identify risks associated with terminal lugs, ensuring optimal performance.

Many engineers overlook this aspect. Documentation often lacks clarity on the specifications of terminal lugs. This can lead to misguided installations. Awareness of potential hazards is crucial. By prioritizing the right standards, we can enhance safety. Electrical systems should never compromise on reliability. Quality terminal lugs, compliant with regulations, are essential for safe operations.