-

Home

-

About Us

-

Products

-

News

-

Application

-

Service

-

Blog

-

Contact Us

Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

-

Whatsapp

In the realm of electronics and electrical engineering, the choice of connectors is pivotal for ensuring reliable and efficient connectivity in various projects. Among the myriad of options available, pin connectors stand out due to their versatility and ease of use. Pin connectors facilitate seamless connections between components, making them indispensable in a wide range of applications, from consumer electronics to industrial machinery. Understanding the different types of pin connectors is essential for anyone looking to enhance their project designs or improve existing circuits.

This article delves into the top 10 pin connector types that every engineer and hobbyist should be familiar with. By exploring the unique features and applications of each connector type, we aim to equip you with the knowledge necessary to select the best option for your specific needs. Whether you are working on a simple prototype or a complex system integration, knowing the right pin connector can make all the difference in achieving optimal performance and reliability in your projects. Join us as we navigate through the essentials of pin connectors and their significance in modern electronics.

Pin connectors play a crucial role in the realm of electronics, serving as the pivotal interface between various components within devices. Defined simply, a pin connector is a type of electrical connector consisting of one or more pins that interlock or fit into corresponding sockets.

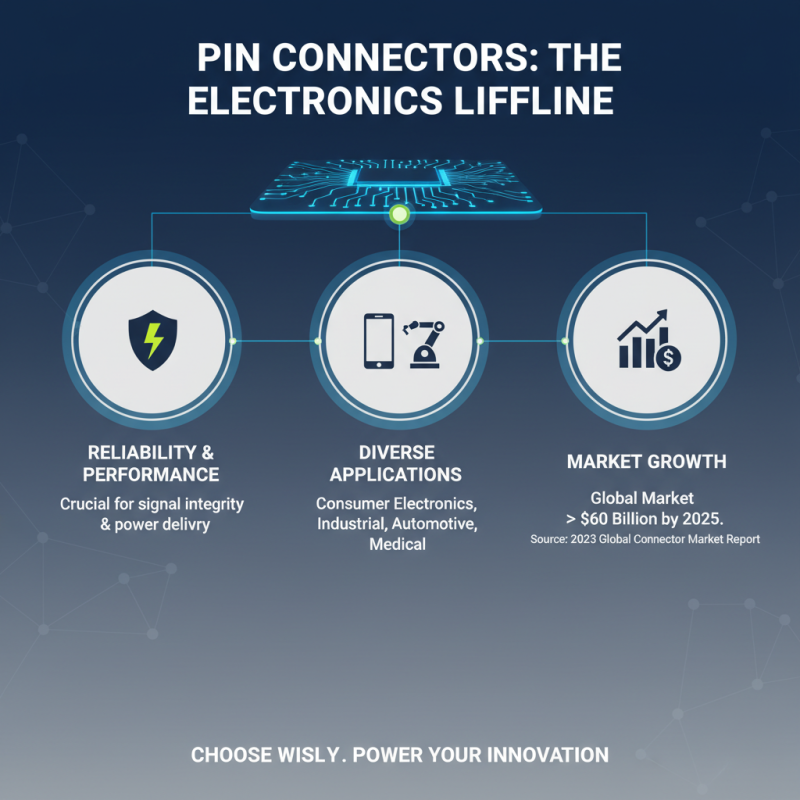

These connectors facilitate the transfer of power and signals, ensuring reliable communication between different parts of an electronic system. Their significance extends beyond mere functionality; the design and selection of pin connectors can impact the overall performance, durability, and efficiency of electronic projects.

The importance of pin connectors is underscored by their wide-ranging applications, from simple consumer gadgets to complex industrial machinery. In many cases, they are essential for achieving a stable connection that withstands frequent use and environmental conditions. Selecting the appropriate pin connector type can also influence assembly ease and maintenance.

With various designs and configurations available, understanding the specific requirements and characteristics of pin connectors is vital for engineers and hobbyists alike. This knowledge empowers them to create robust and high-performing electronic projects that meet both functional and operational demands.

When it comes to electronics, the choice of pin connectors can significantly impact the reliability, efficiency, and performance of a project. This is largely due to the various types of connectors available, each designed for specific applications. According to the "2023 Global Connector Market Report," the overall market for connectors is projected to exceed $60 billion by 2025, highlighting the increasing importance of selecting the right type of pin connector for both consumer and industrial applications.

Among the most common pin connector types, the Molex and header connectors stand out due to their versatility and durability. Molex connectors are frequently utilized in computer hardware and industrial equipment, offering a strong, secure connection that’s easy to assemble. Header connectors, often used on PCBs, provide a simple way to connect wires while ensuring reliable electrical connections. Research indicates that improper pin connector choices can lead to significant failure rates, with an estimated 30% of electronic device failures attributed to connection issues.

Moreover, advancements in technology are driving the innovation of pin connectors, with the market requiring solutions that can support higher data rates and greater power capabilities. The increasing demand for compact and efficient designs in automotive and aerospace industries further emphasizes the need to understand the various types of pin connectors available today. As reported by the International Electrotechnical Commission, choosing the appropriate pin connector can enhance signal integrity and system performance, paving the way for innovative electronic solutions.

When it comes to pin connectors, understanding their distinct features is crucial for ensuring the right fit for your electronics projects. The most common types include male and female connectors, which are designed to work together but vary in configuration. Male connectors typically consist of protruding pins, while female connectors have corresponding sockets. This interplay is essential for secure electrical connections, preventing mishaps caused by incorrect assembly.

Another critical category is the header connectors, which come in various pin counts and orientations. Usually found on printed circuit boards (PCBs), they facilitate easy connection and disconnection. It’s advisable to consider the pin spacing and arrangement to match your board layout. For projects needing flexibility, modular connectors, such as those seen in ribbon cables, provide adaptable options for connecting multiple wires simultaneously.

Tips for selection: Always check the voltage and current ratings of the connectors to ensure compatibility with your project’s requirements. Additionally, consider the physical space available in your design; choosing compact connectors can save space without sacrificing performance. Finally, look for connectors with good mechanical robustness, as durability plays an essential role in maintaining reliable connections in the long run.

Pin connectors are integral components in various projects across multiple industries, serving critical functions in ensuring reliable electrical connections. In consumer electronics, for example, pin connectors are commonly used in devices like smartphones and laptops, facilitating communication between circuit boards and components. Their compact design allows for efficient space management, which is vital for the sleek appearance of modern devices.

In the automotive sector, pin connectors play a crucial role in connecting sensors, control units, and power sources. They provide robust connections that withstand harsh conditions such as vibration, temperature fluctuations, and exposure to moisture. This reliability is essential for safety features, including advanced driver-assistance systems (ADAS) and infotainment systems, making pin connectors a cornerstone in automotive design and function.

Moreover, in industrial applications, pin connectors are essential for robotic systems and automation equipment. They enable data transmission and power distribution, ensuring that machines operate smoothly and efficiently. The ability to quickly connect and disconnect these connectors also simplifies maintenance processes, allowing for timely repairs and upgrades without extensive downtime. As technology evolves, the versatility and importance of pin connectors continue to grow, making them a focal point in the design and operation of modern electronic systems.

When selecting pin connectors for your projects, understanding the specific requirements of your application is crucial. Factors such as the current rating, voltage rating, and the number of pins required should guide your choice. Ensure the connectors can withstand the operating environment, whether it’s temperature variations, moisture, or exposure to dust. It’s also essential to consider the mechanical aspects, such as how frequently the connectors will be mated and unmated. High-cycle applications may necessitate connectors designed for durability and repeated use, whereas lower-frequency use might allow for simpler designs.

In addition to the technical specifications, employing best practices in the installation and usage of pin connectors can significantly enhance the reliability of your project. Ensure that proper soldering techniques are employed if applicable, as good connections minimize resistance and prevent overheating. Using strain relief and securing connectors with appropriate mounts can avoid stress on the pins, which is a common failure point. Furthermore, document your connector configurations and connections thoroughly, which will facilitate troubleshooting and future upgrades. Being meticulous in these aspects will not only prolong the life of your connectors but will also contribute to the overall success of your project.

| Connector Type | Pin Count | Current Rating | Common Applications |

|---|---|---|---|

| D-sub Connector | 9, 15, 25, 37 | 5A | Computers, Communication |

| Molex Connector | 2-12 | 3-5A | Consumer Electronics |

| JST Connector | 2-16 | 1.5A | Battery Packs |

| Wire-to-Board Connector | 2-60 | 3A | Industrial Equipment |

| Header Connector | 2-40 | 2A | PCBs |

| RJ45 Connector | 8 | 1A | Networking |

| Screw Terminal Connector | 2-12 | 10A | Power Supply |

| Pin Header Connector | 2-80 | 2A | Microcontrollers |

| Circular Connector | 3-37 | 10A | Automotive, Aerospace |

| USB Connector | 4-24 | 5A | Computers, Mobile Devices |