-

Home

-

About Us

-

Products

-

News

-

Application

-

Service

-

Blog

-

Contact Us

Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

-

Whatsapp

In the world of electrical connections, reliability is paramount. According to industry expert John Harris, "A quality wire electrical connector can make or break a project." This underscores the importance of selecting the right connectors.

Wire electrical connectors come in various shapes and sizes. Each type serves a specific purpose, from splicing wires to joining multiple circuits. While many options exist, not all connectors offer the same level of stability and performance. Users often overlook the significance of choosing a robust connector until they face issues like corrosion or loose connections.

Understanding the nuances of wire electrical connectors is vital for both professionals and DIY enthusiasts. The right tools can save time and ensure safety in any electrical project. Reflecting on past experiences, one might realize that cutting corners on connectors can lead to costly repairs. The pursuit of reliable connections is essential for successful electrical work.

When it comes to wire electrical connectors, understanding their types and applications is crucial. Various connectors serve different purposes in electrical systems. For example, barrel connectors are commonly used in low-voltage applications. They effectively provide a secure connection. Meanwhile, terminal blocks are essential for organization and easy maintenance. According to industry reports, nearly 70% of electrical failures stem from poor connections. That's significant.

The selection of the right connector impacts performance. Crimp connectors can handle high current loads, making them suitable for robust power applications. In contrast, insulated connectors help prevent accidental shorts. Yet, even with the best connectors, mistakes occur. Incorrect installation remains a frequent issue. Research indicates that 25% of connector failures happen due to human error during installation.

Understanding the environment is also vital. Connectors in outdoor settings need enhanced weather resistance. Heat-shrink connectors provide extra protection against moisture and dirt. As systems grow more complex, so do the requirements for connectors. Many engineers still overlook critical aspects, leading to inefficient designs. Regular reviews and updates could mitigate these issues, enhancing reliability.

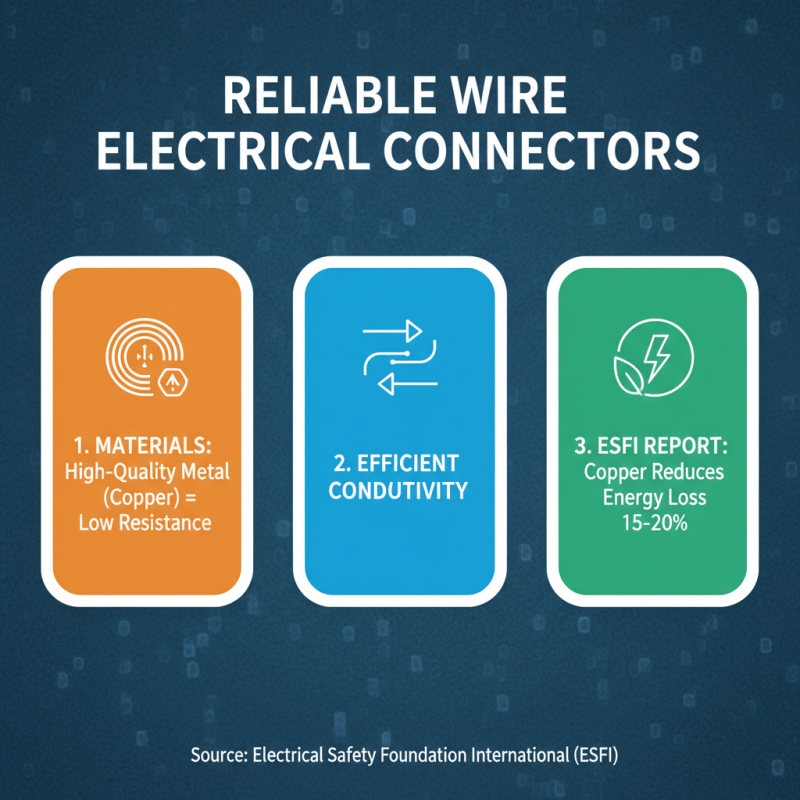

When choosing wire electrical connectors, reliability is crucial. Key features define a connector's effectiveness. First, let's consider the materials used. High-quality metal offers low resistance. This results in efficient conductivity. A recent report by the Electrical Safety Foundation International (ESFI) indicates that connectors made from copper can reduce energy loss by 15-20 percent in various applications.

Next, we have insulation. A well-insulated connector protects against moisture and environmental damage. Connectors rated for outdoor use often have advanced insulation. This increases longevity and performance. According to the National Fire Protection Association (NFPA), improper insulation can lead to a significant percentage of electrical fires.

Furthermore, versatility is a necessary feature. Connectors that accommodate multiple wire sizes allow for flexibility in projects. However, not all connectors perform well under stress or temperature changes. Underestimating the impact of poor quality leads to dire consequences. Installing connectors in inaccessible places can complicate replacement. Investing time in choosing the right connectors will prevent stakes later on.

When it comes to wire electrical connectors, strength and durability are critical. According to a recent industry report, over 30% of electrical failures occur due to poor connections. This statistic highlights the importance of using high-quality connectors. Durable connectors provide better resistance to corrosion and wear, which are common issues in electrical systems. Selecting the right material, such as copper or aluminum, can enhance longevity.

Additionally, connectors that meet industry standards often experience higher performance. Research indicates that connectors rated for high voltage and heavy current can maintain integrity under stress. In certain environments, such as outdoors or in humid conditions, failure rates increase without proper sealing. Certain designs, like heat-shrink connectors, can offer improved weather resistance. However, installation errors can compromise these advantages, leading to malfunctions. Regular inspections and maintenance can also ensure that the connections remain functional over time.

When choosing wire electrical connectors, performance and reliability are key factors. The variety of connectors available can make selection daunting. This often leads to confusion over which type suits specific needs. Reliable connections result in efficient electrical systems. Without proper connections, failures can occur, leading to potential hazards.

Connector materials play a crucial role in performance. Copper and aluminum are common choices. However, not all connectors are made of high-quality materials. Some may corrode or deteriorate over time. This can create resistance and heat, leading to failures. Inspecting connectors regularly can prevent unexpected issues. It is essential to watch for signs of wear and damage.

Performance ratings also vary among different types of connectors. Some connectors excel in high-temperature environments, while others may struggle. Understanding the environment where connectors will be used is vital. Even small mistakes can lead to serious consequences. Relying solely on specifications can be misleading. Testing connectors in real conditions offers a clearer picture of their reliability. This practical approach can avoid costly surprises down the line.

Proper installation of wire electrical connectors is crucial for ensuring reliable connections. Start by selecting the right connector for your project. Ensure that the wire gauge matches the connector specifications. This small detail can prevent overheating and potential failures.

When stripping the wires, be careful not to damage the strands. Too much exposure can lead to corrosion over time. A common mistake is leaving too much insulation on the wire. This can result in poor electrical contact. Remember, a tight connection improves conductivity.

While crimping connectors, maintain consistent pressure. Uneven crimping can create weak points. Inspect each connection for visible signs of wear or damage. A quick visual check can save you from bigger issues later.

Occasionally, double-check your work. It helps to catch mistakes before they escalate. Avoid rushing; careful installation pays off in the long run.