-

Home

-

About Us

-

Products

-

News

-

Application

-

Service

-

Blog

-

Contact Us

Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

-

Whatsapp

In the world of electrical installations and repairs, choosing the right components is crucial for ensuring safety and efficiency. As expert electrical engineer James Carter once stated, "The reliability of your wiring systems largely depends on the quality of your cable wire connectors." This emphasizes the critical role that cable wire connectors play in any wiring endeavor, whether for residential, commercial, or industrial applications.

With numerous options available on the market, selecting the best cable wire connectors can be daunting. Factors such as material, insulation, and compatibility with different wire types must be considered to ensure optimal performance and longevity. In this article, we will explore the top ten cable wire connectors that are highly recommended for various wiring needs. We aim to provide you with a comprehensive understanding of what to look for in these essential components, ensuring that your connections remain secure and reliable, no matter the project at hand.

Cable wire connectors play a crucial role in ensuring reliable electrical connections across various applications, from residential wiring to industrial setups. According to a report by MarketsandMarkets, the global wire connectors market is projected to reach USD 7.76 billion by 2025, driven by the growing demand for efficient power management and the increasing prevalence of automation technology. These connectors come in various types, each serving a specific function, such as maintaining a secure and stable connection, preventing short circuits, and facilitating the easy replacement of wires.

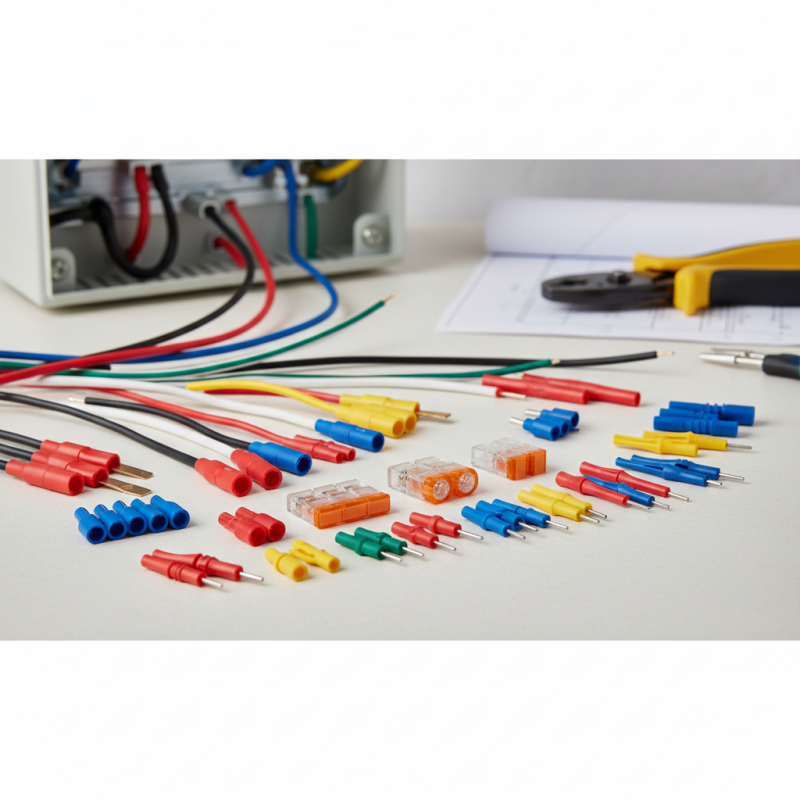

Understanding the different types of cable wire connectors is essential for making informed decisions about your wiring needs. The most common types include spade connectors, ring terminals, and butt connectors, each designed for specific scenarios. For instance, spade connectors are ideal for equipment that may require frequent disconnection, while butt connectors are used in permanent connections to join two wires together. Additionally, proper use of these connectors can enhance the longevity of electrical systems and reduce maintenance costs. The International Electrotechnical Commission notes that incorrect connections are a significant cause of electrical failures, highlighting the importance of selecting high-quality connectors tailored to the specific demands of each project.

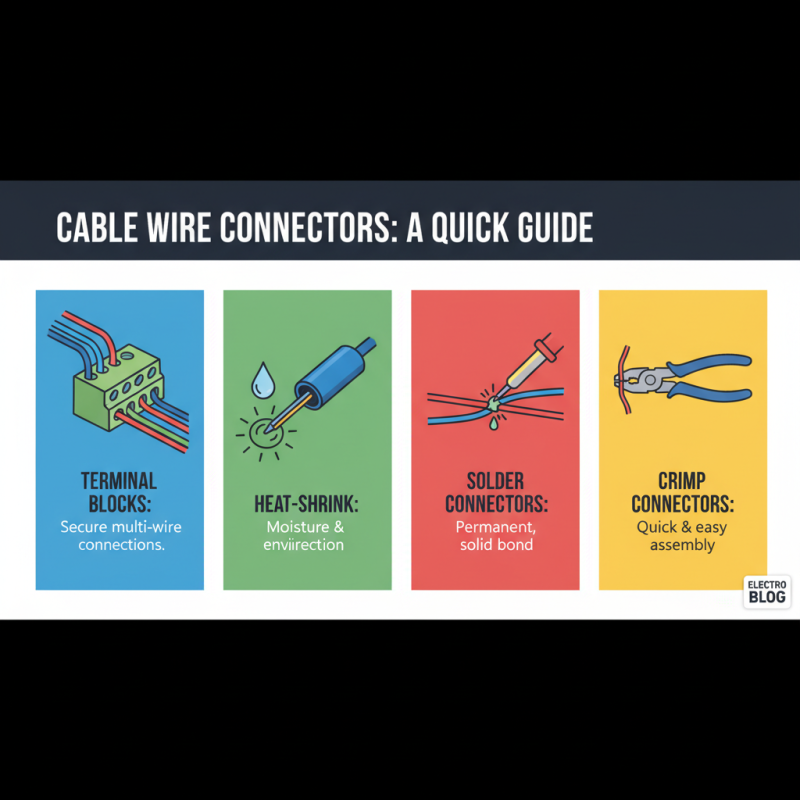

When it comes to wiring projects, choosing the right cable wire connectors is essential for ensuring reliable electrical connections. There are several types of cable wire connectors available, each designed for specific applications and environments. Among the most common types are terminal blocks, which provide a secure connection for multiple wires, and heat shrink connectors that offer enhanced protection against moisture and environmental factors. Solder connectors, on the other hand, create a permanent bond for a solid electrical connection, while crimp connectors allow for quick and easy assembly in various wiring setups.

Additionally, wire nuts and twist-on connectors are popular choices for residential wiring, facilitating easy installation and disconnection when necessary. For outdoor applications, waterproof connectors are essential to prevent corrosion and electrical failures. Each type serves distinct purposes and should be selected based on factors such as ease of use, environmental considerations, and the specific requirements of the electrical system. Understanding these different types of cable wire connectors will help you make informed decisions for your wiring needs, ensuring effective and safe electrical performance.

When selecting cable wire connectors, several factors should be considered to ensure optimal performance and reliability in your wiring projects. One critical aspect is the connector's material. Connectors made from copper or brass typically provide better conductivity. According to the International Electrotechnical Commission (IEC), connectors with high-purity materials can significantly reduce resistance, improving the overall efficiency of electrical circuits. Furthermore, the insulation type is essential; connectors with robust insulation can prevent moisture ingress and reduce the risk of short circuits.

Another important consideration is the compatibility of connectors with your wiring type. It is crucial to ensure that the connectors match the gauge and insulation of your cables. According to a recent report by the National Electrical Manufacturers Association (NEMA), improper sizing can lead to overheating and eventual failure of electrical systems. Conducting a proper gauge assessment before purchasing connectors can save time and ensure safety in electrical installations.

Tips: Always check for the connector's current and voltage ratings to match your specific needs. Additionally, consider the environmental conditions where the connectors will be used, as some connectors are designed for harsher conditions, such as outdoor use or exposure to chemicals. By taking these factors into account, you can choose the right cable wire connectors for your wiring requirements, ensuring durability and reliability in your electrical systems.

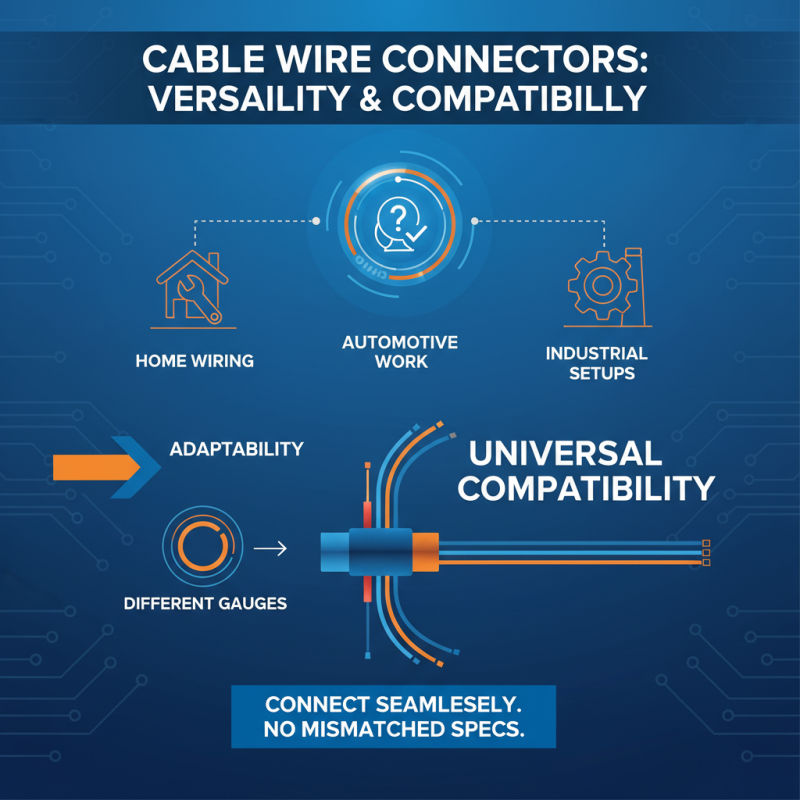

When it comes to cable wire connectors, understanding their features and benefits is essential for making informed decisions about your wiring needs. One of the most critical attributes to consider is the connector's compatibility with various wire types. Many connectors are designed to accommodate different gauges, making them versatile for assorted applications, whether in home wiring, automotive work, or industrial setups. This adaptability ensures that you can seamlessly connect wires without worrying about mismatched specifications.

Another vital feature to look for is the durability of the connectors, which often includes resistance to environmental factors such as moisture, temperature fluctuations, and corrosion. High-quality connectors are typically made from robust materials that promise longevity and reliability, reducing the risk of failure over time. Additionally, ease of installation is a benefit worth highlighting, as many connectors are designed for simple and efficient assembly, allowing users to complete projects quickly without extensive tools. Overall, prioritizing these features will help you select the best cable wire connectors for your specific needs, enhancing both safety and performance in your wiring projects.

When working with cable wire connectors, proper installation is crucial to ensure optimal performance and longevity.

First, it’s important to prepare the wires correctly. Strip the insulation evenly and avoid excessive exposure of the conductor. This helps prevent any potential short circuits while ensuring a strong connection.

Another key tip for installation is to pay attention to the torque specifications when tightening connectors. Over-tightening can damage the wire or degrade the connection, while under-tightening can lead to intermittent connections. Using a torque wrench can help achieve the right tension without risking connection integrity.

Lastly, always make sure to choose the right type of connector for your specific application. For example, moisture-resistant connectors are essential in outdoor or wet environments to prevent corrosion and ensure durability. Following these steps will maximize the performance of your cable wire connectors and provide reliable results for all your wiring needs.