-

Home

-

About Us

-

Products

-

News

-

Application

-

Service

-

Blog

-

Contact Us

Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

-

Whatsapp

In the world of manufacturing, choosing the right Cable Wire Harness is crucial. Dr. Emily Carter, a leading expert in electrical engineering, once said, “The right harness can dictate the success of an entire project.” Indeed, Cable Wire Harnesses are not just components; they are the lifelines of electronic systems.

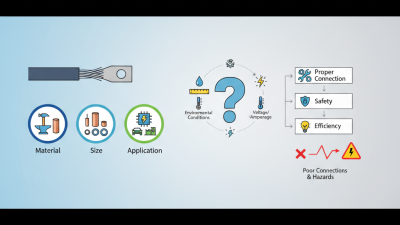

When selecting a Cable Wire Harness, factors like design, material, and application must be considered. Different projects require specific types of harnesses, which can complicate the selection process. For instance, automotive applications demand robust wiring, while medical devices may need lightweight and flexible harness solutions. Each industry has its unique requirements.

However, many overlook the importance of custom solutions. A generic harness may not fit perfectly, leading to potential issues. Ignoring these details can cause inefficiencies or even failures. It’s necessary to reflect on the exact needs of your project when sourcing a Cable Wire Harness. Make informed decisions to ensure your project's success.

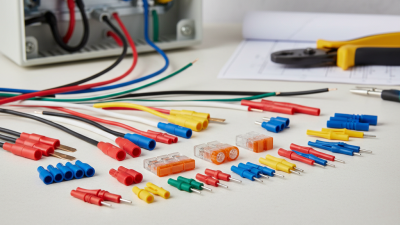

Cable wire harnesses play a crucial role in modern electronics. They are used to organize and protect multiple cables. Essentially, a wire harness is a collection of wires bundled together. This setup simplifies installation and maintenance. However, not all harnesses are created equal. The design must consider the project's specific needs.

In many cases, users overlook the complexity of wire harness design. Different environments require different materials. For example, harnesses in automotive applications need to withstand heat and vibrations. An outdoor application may prioritize UV resistance. Choosing the right connectors is also vital. Poor selections lead to connectivity issues later on.

Moreover, the assembly process can be challenging. Mistakes in measurements can lead to costly rework. Testing each harness thoroughly before installation is often neglected. This can result in failures down the line. It's essential to recognize that each project is unique. A one-size-fits-all approach rarely works in the long run. Collaborating with professionals can enhance the outcome significantly.

When selecting cable wire harnesses, it’s essential to understand the variety available. Different applications call for specific types. Typically, the common varieties include standard wire harnesses, custom harnesses, and over-molded harnesses. Each type has a unique construction and purpose, which influences performance and efficiency. Reports suggest that custom wire harnesses, for instance, account for approximately 65% of the market in specialized applications.

Standard wire harnesses are often used in consumer electronics. They are cost-effective and widely available. However, they lack customization. Over-molded harnesses provide enhanced durability and protection. These are ideal for harsh environments, but manufacturing them can be complex. A study revealed that 40% of project delays stem from inadequate harness design and integration.

Attention to detail is crucial in harness production. Each wire, connector, and sleeve must fit perfectly. Minor discrepancies can lead to failure. Many engineers overlook the need for testing before deployment. Reports indicate that 70% of harness-related issues arise from inadequate pre-production quality checks. This highlights the need for thorough validation processes. Reflection on previous projects can illuminate areas for improvement.

This chart illustrates the most common types of cable wire harnesses used in various applications, highlighting their prevalence and suitability for different project requirements.

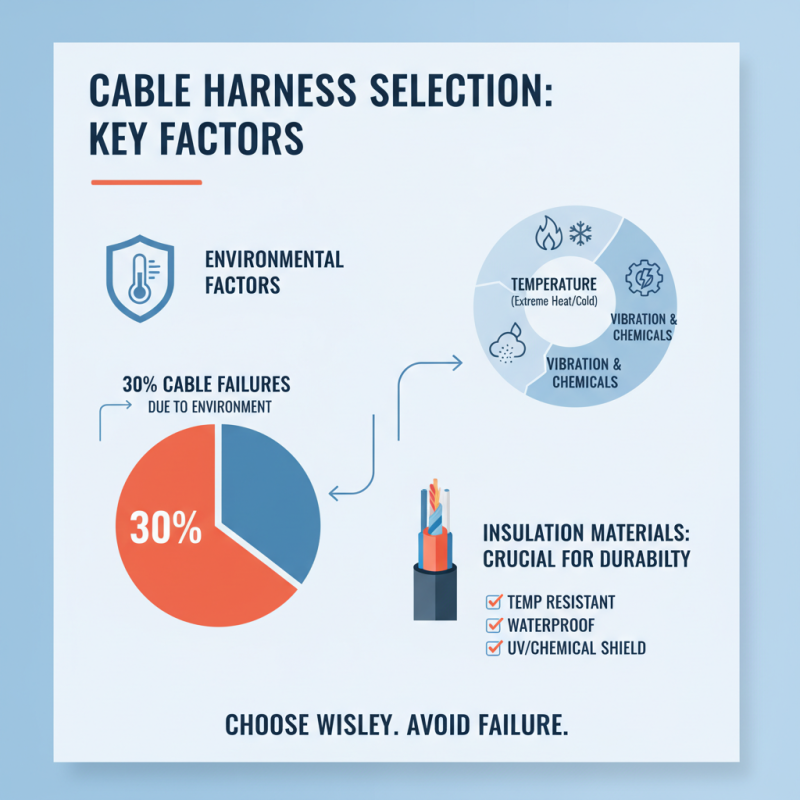

When selecting a cable wire harness type, several factors come into play. The environment where the harness will be used is crucial. A harness exposed to extreme temperatures requires materials that can withstand these conditions. According to industry reports, over 30% of cable failure incidents are due to environmental factors. This indicates the importance of selecting suitable insulation materials.

Another essential consideration is the complexity of the wiring system. A simple harness design may suffice for straightforward applications. However, more complicated systems demand higher precision and more advanced design. Data from recent studies show that poorly designed wire harnesses can lead to up to a 25% increase in failure rates. This suggests that investing in a professionally designed harness can pay off in the long run.

It's also vital to analyze the weight and flexibility of the harness. In aerospace and automotive applications, lightweight materials are favored. These help improve efficiency and performance. Yet, an overly flexible harness could result in tangling or damage during installation. Balancing these properties is key. Users should often reassess their choices and potential impacts on project outcomes.

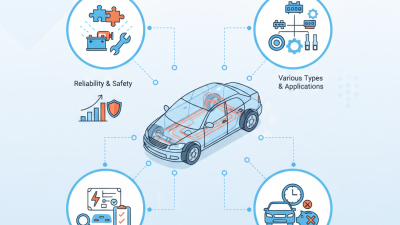

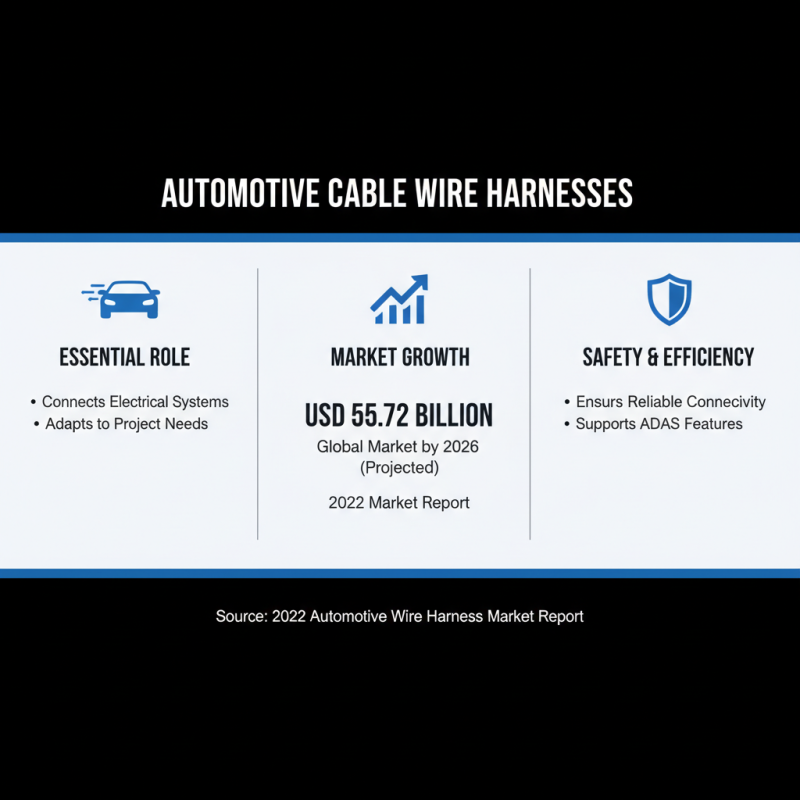

Cable wire harnesses play essential roles across various industries, adapting to unique project needs. In automotive manufacturing, they provide critical connectivity for electrical systems. According to a 2022 market report, the global automotive wire harness market is projected to reach USD 55.72 billion by 2026, showcasing high demand. These harnesses ensure safety and efficiency, supporting features like advanced driver-assistance systems (ADAS).

In the aerospace sector, wire harnesses must meet stringent standards. They often undergo rigorous testing to withstand extreme temperatures and vibrations. A recent study indicated that 30% of aerospace failures relate to wiring issues. Addressing these challenges requires careful design and material selection, highlighting the importance of quality.

The medical industry also utilizes specialized cable wire harnesses for complex devices. These harnesses must be reliable, as they often connect life-saving equipment. A report from 2021 noted that 40% of medical device recalls were linked to electrical failures. This statistic emphasizes the need for precision. Not every solution fits all, and some harness designs might struggle to meet specific regulatory requirements. Manufacturers must continually innovate. Balancing cost and quality remains a persistent challenge in this competitive environment.

When designing cable wire harnesses, attention to detail is crucial. Start with a clear understanding of your project's requirements. Identify the types of cables and connectors you will use. This helps avoid potential mismatches later. Ensure that your design can accommodate expected environmental conditions, such as temperature and moisture. Take time to test different materials for durability.

Consider the arrangement of wires within the harness. Overlapping cables can lead to signal interference and damage. Aim for neatness in your layout. A well-organized harness saves time during installation and maintenance. Use color coding to simplify wiring. This makes it easier to identify connections at a glance.

Regularly review your initial designs. Seek feedback from technicians who will actually use the harnesses. They can provide insights that improve functionality. Remember, perfection is often an ongoing process rather than a one-time goal. Embrace the learning experience and adjust accordingly.

| Harness Type | Material | Application | Temperature Range (°C) | Connector Type |

|---|---|---|---|---|

| Standard Wire Harness | PVC | Electronics | -20 to 85 | Crimp Connector |

| Automotive Wire Harness | XLPE | Vehicles | -40 to 120 | Pin Connector |

| Industrial Wire Harness | TPE | Factories | -10 to 80 | Socket Connector |

| Medical Wire Harness | Silicone | Medical Devices | 0 to 100 | Miniature Connector |

| Aerospace Wire Harness | PTFE | Aircraft | -55 to 150 | Circular Connector |