-

Home

-

About Us

-

Products

-

News

-

Application

-

Service

-

Blog

-

Contact Us

Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

-

Whatsapp

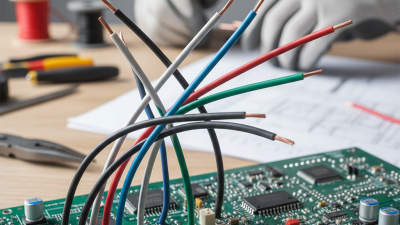

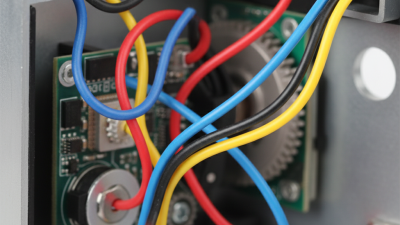

When embarking on electrical projects, one critical component stands out: Terminal Blocks. These simple devices facilitate connections between wires in a safe and efficient manner. By serving as a central point for electrical circuits, they ensure that power flows smoothly. Each Terminal Block has various specifications, making the selection process vital for project success.

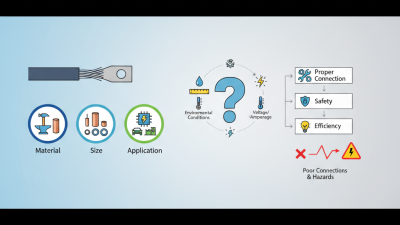

Choosing the right Terminal Blocks can be daunting. The market is filled with options that vary in material, size, and configuration. Some Terminal Blocks are designed for specific environments, like high humidity or extreme temperatures. Understanding these details can greatly impact the durability and performance of your project.

Consider the installation process too. Sometimes, even experienced professionals overlook the significance of proper mounting. A well-installed Terminal Block can prevent potential hazards. However, it takes time and practice to master the technique. Reflecting on such experiences can lead to better outcomes in future projects. Making the right choice can feel overwhelming, but it is essential for your electrical work.

Terminal blocks are essential components in electrical projects. They offer a structured way to connect wires securely. Their design allows for easy installation and maintenance. When connecting multiple wires, these blocks simplify the process greatly. Terminal blocks can save you time and reduce the risk of errors.

Understanding the purpose of terminal blocks is crucial. They help manage electrical connections efficiently. By organizing wires neatly, they make troubleshooting easier. However, it’s important to select the right type. Not all terminal blocks are suitable for every application. Some may not handle high voltage or current well. It could be tempting to use a block beyond its capacity. This can lead to failures or hazards.

In practice, always consider the specifics of your project. What type of wires are you using? What is the environment like? Ensuring compatibility is key. Reflecting on your choices helps avoid mistakes. It’s a valuable lesson in electrical work. Recognizing this can enhance your projects significantly.

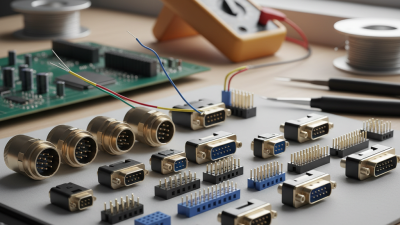

When working on electrical projects, understanding terminal blocks is essential. They provide a secure method for connecting and organizing wiring. Various types are available, each serving specific needs.

One common type is the screw terminal block. This design uses screws to secure wires. It offers a reliable connection but can be time-consuming to install. Another option is the push-in terminal block. This variety allows for quicker connections, making it easier for less experienced users. Consider your project's requirements when choosing.

**Tips:** Always assess wire gauge compatibility. Using the wrong size can lead to problems. Pay attention to insulation ratings. They should match your project's voltage needs.

Barrier terminal blocks are also worth considering. They allow you to separate different circuits. This can be useful for safety and organization. However, routing wires may become more complex.

**Tips:** Label your wires clearly. This practice helps prevent confusion later. Keep a checklist of your connections to avoid errors.

This chart illustrates the popularity of different types of terminal blocks for electrical projects based on their usage frequency. It provides an overview of options available, helping you make informed decisions for your projects.

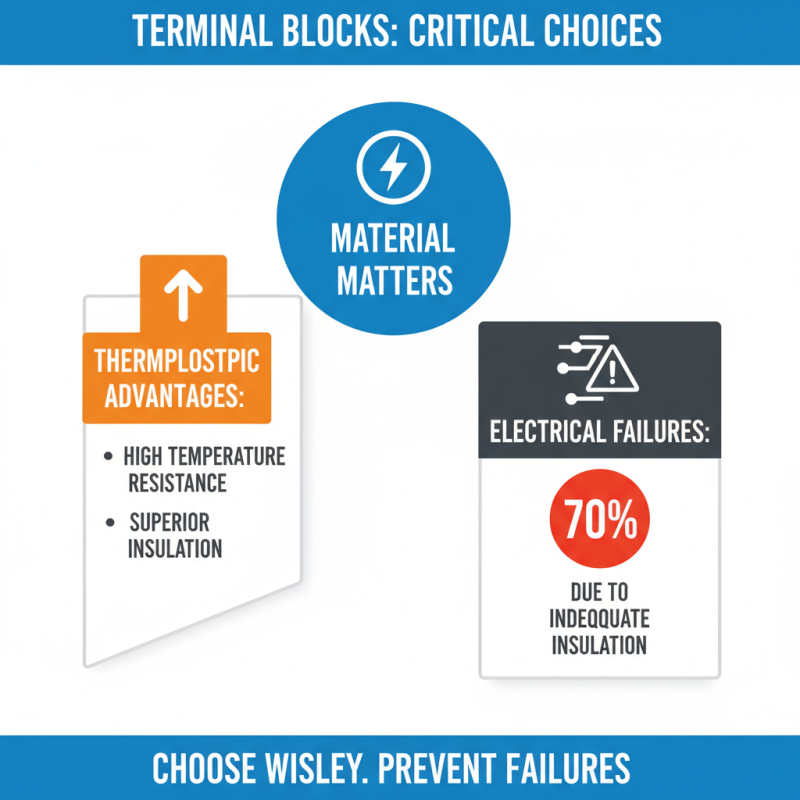

When choosing terminal blocks for electrical projects, several key features stand out. The material of the terminal block is critical. Thermoplastic materials, for instance, can withstand high temperatures and provide better insulation. According to a recent industry report, nearly 70% of electrical failures occur due to inadequate insulation. Therefore, selecting the right material is crucial.

Another important factor is the current and voltage ratings. A study has highlighted that 25% of project delays are due to mismatched ratings. Ensure your terminal blocks can handle the specific load of your application. Check the specifications carefully. Affordability often leads to compromises on ratings. However, this could result in safety risks or equipment failure.

Ease of installation is also a vital aspect. Consider the tools required for securing connections. Complicated setups can lead to mistakes. In fact, survey results show that 40% of electricians struggle with installation issues. Simple designs that allow quick connections often save time and reduce human error. Responding to these elements can enhance the reliability and efficiency of electrical projects.

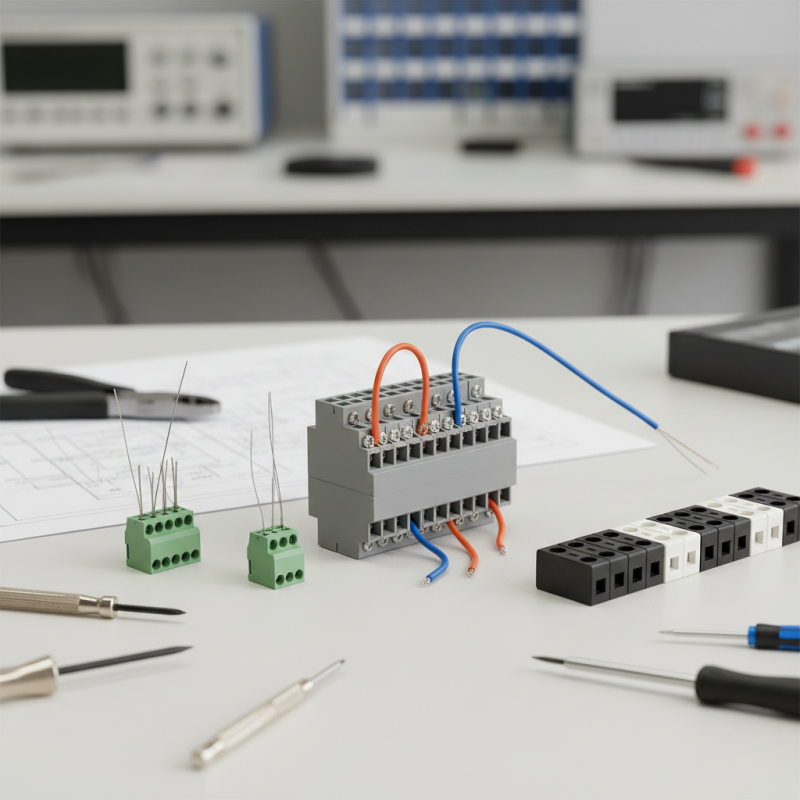

When choosing terminal blocks for electrical projects, several brands and models stand out. Each offers unique features that cater to various needs. For hobbyists and professionals alike, reliability is crucial. Look for models with high-rated insulation and robust connections. This ensures safety and efficiency in your project setup.

Different terminal blocks come in various sizes and colors. This makes it easier to organize projects. Some designs are compact, perfect for small spaces. Others have more connection points, allowing for greater flexibility. Consider the material as well. Some blocks are made of sturdy plastics, while others use metals for durability. This choice can affect performance in high-stress environments.

Reading user reviews can reveal important insights. Sometimes, a highly rated product may not meet your specific needs. Installation may also pose challenges, especially for beginners. A straightforward design can save time and frustration. Don't rush into a decision. Consider factors like your project scale and environment.

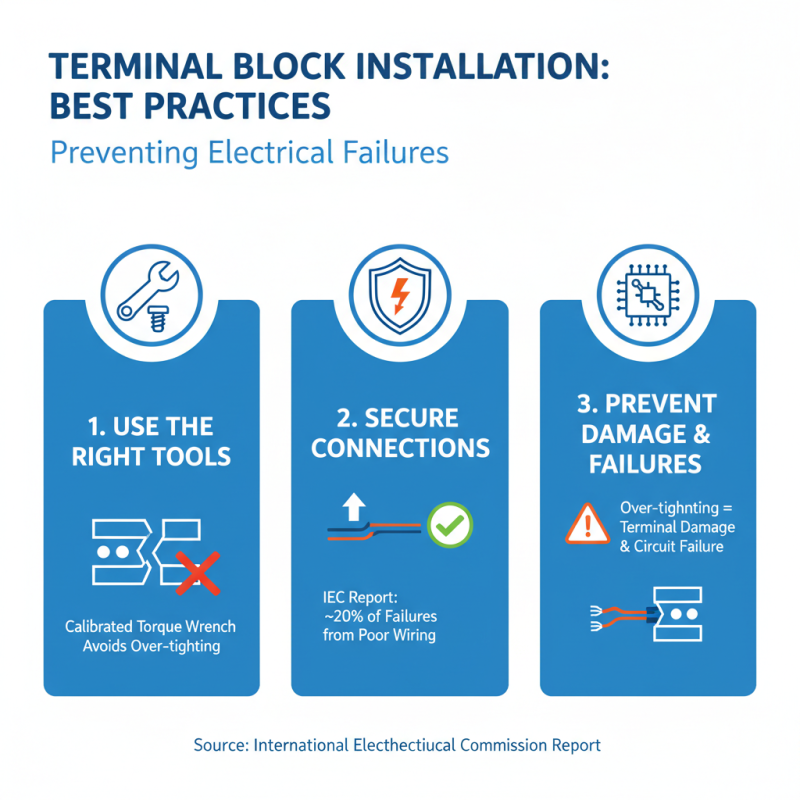

When installing terminal blocks, ensuring proper connections is crucial. According to a report from the International Electrotechnical Commission, nearly 20% of electrical failures are due to poor wiring practices. Using the right tools is essential. A well-calibrated torque wrench can help prevent over-tightening. Over-tightening can lead to terminal block damage and potential circuit failure.

Maintaining terminal blocks is just as vital. Regular inspections can catch issues early. Corrosion is a common problem, especially in humid environments. It can compromise electrical conductivity. Furthermore, keeping connections clean helps maintain efficiency. A study from the Institute of Electrical and Electronics Engineers found that clean connections can improve performance by up to 15%.

It’s essential to record the installation conditions. This data should include temperature and humidity levels at the time of installation. Such details help in future maintenance planning. Many overlook this step, leading to repeated issues over time. Observing environmental factors can provide insights that improve long-term reliability.