-

Home

-

About Us

-

Products

-

News

-

Application

-

Service

-

Blog

-

Contact Us

Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

-

Whatsapp

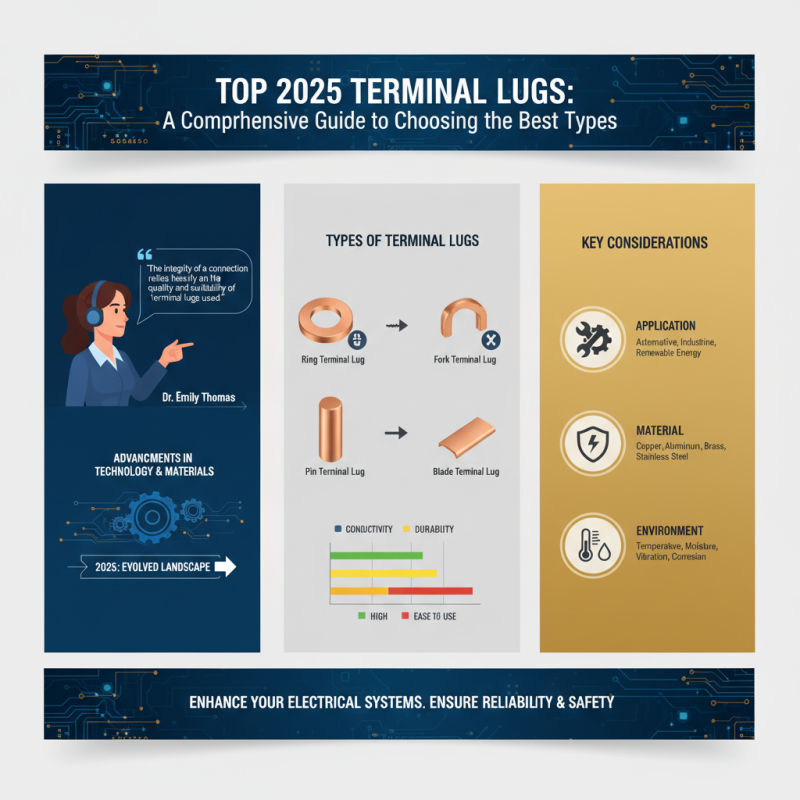

In the world of electrical connections, choosing the right components is crucial for ensuring safety and efficiency. Terminal lugs, essential for securely connecting wires to terminals, play a pivotal role in various applications, from automotive to industrial settings. As electrical engineer and industry expert, Dr. Emily Thomas, once said, "The integrity of a connection relies heavily on the quality and suitability of terminal lugs used." This statement underscores the importance of understanding the different types of terminal lugs available on the market.

This comprehensive guide aims to illuminate the various options in terminal lugs, helping you make informed decisions based on your specific needs. With advancements in technology and materials, the landscape of terminal lugs has evolved significantly, presenting both opportunities and challenges for users. By exploring the best types of terminal lugs in 2025, we will equip you with the knowledge to enhance your electrical systems while ensuring reliability and safety. Join us as we delve into the intricacies of terminal lugs and empower your connectivity solutions.

Terminal lugs are crucial components in electrical systems, enabling reliable connections between wires and terminals. Understanding the various types of terminal lugs and their specific applications can significantly enhance the efficiency and safety of your electrical projects. There are several common types of terminal lugs, including ring lugs, spade lugs, and pin lugs, each designed for distinct functions. Ring lugs, for instance, provide a solid connection that is often used for grounding applications, while spade lugs offer ease of connection and disconnection, making them ideal for devices that require frequent maintenance.

When selecting terminal lugs for your project, it's essential to consider the electrical ratings, material compatibility, and environmental factors. For example, copper lugs are typically favored for their excellent conductivity, but if the application involves exposure to moisture or corrosion, opting for tin-plated or stainless steel lugs might be wise.

**Tips:** Always ensure that the terminal lug matches the gauge of the wire being used to prevent overheating and ensure proper connectivity. Additionally, consider using heat-shrink tubing for added protection against environmental conditions. When in doubt, refer to manufacturer specifications to guarantee compatibility and compliance with safety standards.

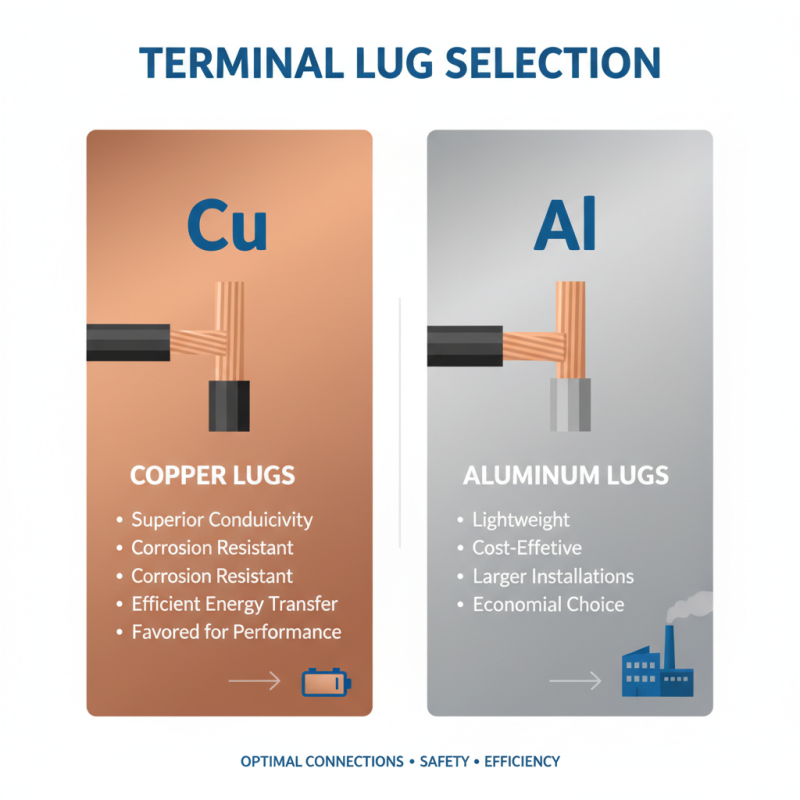

When selecting terminal lugs for your electrical connections, several key factors must be considered to ensure optimal performance and safety. One of the primary considerations is the material of the terminal lug. Generally, copper and aluminum are the most prevalent materials used. According to recent industry reports, copper lugs are favored for their superior conductivity and resistance to corrosion, making them ideal for applications requiring efficient energy transfer. Aluminum, while less conductive than copper, is often chosen for its lightweight properties and cost-effectiveness, particularly in larger installations.

Another critical factor is the current carrying capacity, which depends on both the size and type of the terminal lug. As highlighted in the National Electrical Code (NEC), it is essential to choose a lug that can handle the specific amperage of your application to prevent overheating and potential failure. Additionally, the lug's insulation and sealing capability play significant roles in ensuring long-term reliability in harsh environments. Industry statistics indicate that improper selection of terminal lugs can lead to up to 30% of electrical failures in industrial applications, underscoring the importance of thorough evaluation during the selection process. Proper consideration of these factors will not only enhance performance but also significantly reduce the risk of system failures.

When selecting terminal lugs, understanding the materials from which they are made is crucial for ensuring performance and longevity. Common materials for terminal lugs include copper, aluminum, and steel, each possessing unique characteristics that cater to different applications. Copper, known for its excellent conductivity and durability, is often the preferred choice for high-performance electrical connections. Its resistance to corrosion and ability to withstand high temperatures make it suitable for demanding environments. However, copper lugs can be more expensive, which may impact budgeting for larger projects.

Aluminum terminal lugs are frequently chosen for their lightweight nature and cost-effectiveness. While aluminum doesn’t conduct electricity as efficiently as copper, advancements in metallurgical technology have improved its performance, allowing for broader applications in various industries. One consideration with aluminum lugs is the need for proper surface treatment to prevent oxidation, which can hinder conductivity over time.

Steel, on the other hand, is not commonly used for electrical applications but may be appropriate in mechanical connections due to its strength and resistance to breaking. Choosing the right material ultimately depends on the specific requirements of the application, including environmental factors, electrical load, and budget constraints.

When it comes to ensuring optimal performance of terminal lugs, installation techniques play a crucial role. The first step is to select the appropriate lug type that fits the wire gauge and application requirements. Proper stripping of the wire is essential; ensure that the insulation is stripped back to the appropriate length to make a secure connection without exposing excessive wire. This helps create a reliable electrical path and minimizes potential shorts.

During the installation process, crimping the terminal lug onto the wire must be done with precision. Utilizing a quality crimping tool that matches the lug's specifications will help establish a strong mechanical bond. The crimp should be inspected to confirm that the wire strands are properly compressed and that there are no visible gaps. Additionally, it is vital to check for any corrosion or contaminants on the surfaces of both the lug and the connection point to ensure a clean and conductive interface. By following these techniques, one can significantly enhance the performance and longevity of terminal lugs in various electrical systems.

Proper maintenance of terminal lugs is essential for ensuring their longevity and reliability, especially in applications where consistent performance is critical. One of the primary ways to enhance the lifespan of terminal lugs is through regular inspection. Periodically checking for signs of corrosion, wear, or damage can help catch potential issues before they escalate. Ensuring that connections are tight and free from contaminants can prevent the buildup of dirt and moisture, which can compromise the conductance and overall function of the lugs.

Another important aspect of maintenance is cleaning. Keeping terminal lugs clean can significantly prolong their operational life. Use a suitable cleaner and non-abrasive materials to remove any oxidation or corrosion that may build up over time. Additionally, applying a protective coating after cleaning can help shield the lugs from environmental factors that contribute to deterioration.

Proper storage is also critical; terminals should be stored in a dry environment to minimize exposure to moisture and other damaging elements. By following these maintenance tips, users can ensure that terminal lugs perform effectively for extended periods, reducing the need for premature replacements.