Top Quality Wire Connectors from China's Leading Factory | Wholesale Supply

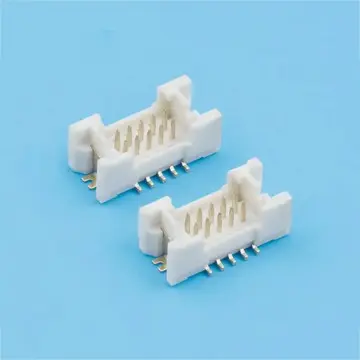

As a premier B2B supplier, we proudly present ourselves as a reliable factory for high-quality Wire Connectors in China. Our focus on quality and innovation positions us as a trusted partner for wholesalers, manufacturers, and businesses across various industries. With extensive experience, we offer a comprehensive range of Wire Connectors tailored to meet diverse industry requirements. We emphasize building strong partnerships through exceptional customer service and competitive pricing. At Zhejiang Wenda Electronics Co., Ltd., we deliver not only products but also valuable support throughout your purchasing journey. Whether you require small or large orders, our flexible manufacturing capabilities can accommodate your needs. Join our satisfied clientele and experience the benefits of partnering with a reputable factory in China. Let’s work together to elevate your business with superior Wire Connectors.In-Depth Analysis of Methods China Leading Wire Connecters Factory Custom Solutions, From Concept to Delivery

In the competitive landscape of Wire Connectors, understanding the journey from concept to delivery is crucial for global procurement professionals aiming to source high-quality products. Established in March 2007, a leading factory in China has emerged as a pivotal player in the custom solutions market, leveraging its extensive experience and robust infrastructure. With over 500 dedicated employees and a manufacturing facility that exceeds 25,000 square meters, the factory is well-equipped to meet the intricate needs of various industries. The factory's operational excellence is rooted in its state-of-the-art production capabilities and a commitment to quality assurance. By utilizing advanced technologies and methodologies, the factory transforms innovative ideas into tangible products. Each phase, from initial design and prototyping to mass production and logistics, is meticulously crafted to ensure timely delivery and optimal performance. Global buyers can take advantage of the tailored solutions offered to meet specific applications, thereby enhancing their competitive edge in the market. With a focus on customer satisfaction and continuous improvement, the factory collaborates closely with clients to refine specifications and address challenges throughout the procurement process. This collaborative approach not only boosts product reliability but also fosters long-term partnerships, making it an attractive choice for international buyers looking to streamline their supply chains. Emphasizing efficiency and quality, the factory stands ready to support the evolving demands of the global market.

In-Depth Analysis of Methods China Leading Wire Connecters Factory Custom Solutions, From Concept to Delivery

| Method | Description | Advantages | Challenges | Applications |

|---|---|---|---|---|

| Injection Molding | A manufacturing process for producing parts by injecting material into a mold. | High production rates, repeatability, and ability to create complex shapes. | High initial cost for mold design and manufacturing. | Automotive Connectors, electronic applications. |

| Die-Casting | Metal casting process that forces molten metal into a mold cavity. | Excellent dimensional accuracy and surface finish. | Limited to non-ferrous metals and high setup costs. | Electrical housings, appliance components. |

| 3D Printing | Additive manufacturing process that creates parts layer by layer. | Flexibility in design, rapid prototyping, and low volume production. | Slower production speed for large quantities and potential material limitations. | Prototype connectors and custom design projects. |

| Laser Cutting | A technology that uses a laser to cut materials with high precision. | High precision, reduced material waste, and versatility. | Limited thickness for some materials and higher operational costs. | Fabrication of connector components and custom shapes. |

| Crimping | A process to join two pieces of metal by deforming one or both of them. | Strong, electrical connections without soldering. | Requires precise tooling and quality control to ensure connection integrity. | Wire Connectors in automotive and aviation industries. |

Top 5 China Leading Wire Connecters Factory Service Backed by Expertise in 2025

M

Matthew Walker

Great quality items backed by knowledgeable staff. They really care about their customers!

28 May 2025

N

Natalie Ramirez

The quality of the products is fantastic! Support was friendly and quick.

30 June 2025

E

Eleanor Cox

Impressive quality! Customer service made every step easy and enjoyable.

20 June 2025

L

Lily Carter

Impressed by the product quality and the professionalism of their support staff.

20 May 2025

J

Jack Rivera

Quality exceeds expectations! The service team was a pleasure to work with.

20 June 2025

A

Ava Ramirez

Quality assurance is evident in their products! The staff was very helpful.

22 May 2025