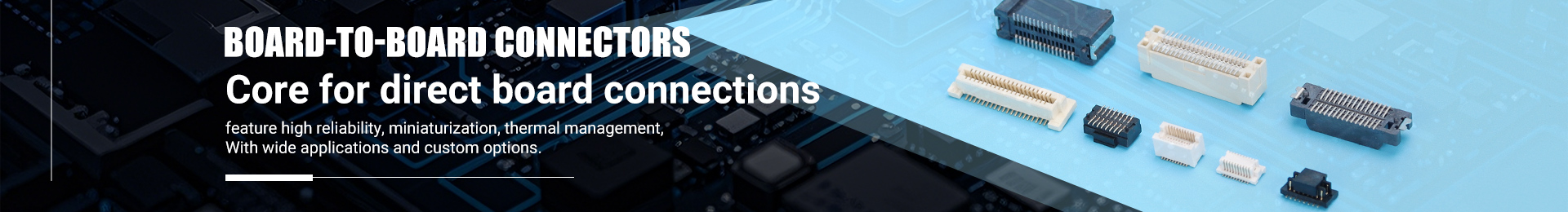

China's Leading Faston Connector Manufacturer - High-Quality Suppliers & Production

As a trusted provider of high-quality Faston Connectors, I recognize the specific requirements of B2B buyers. Our products, produced at Zhejiang Wenda Electronics, reflect exceptional precision and craftsmanship, establishing us as a premier Faston Connector manufacturer in China. By partnering with us for wholesale purchases, you are choosing a reliable supplier committed to quality and efficiency. We offer a comprehensive selection of Faston Connectors, designed to cater to diverse industrial needs. With years of experience, our factory enforces stringent quality control measures to ensure that every product exceeds industry standards. Our focus on building strong partnerships drives us to deliver outstanding customer service and support. For those seeking dependable wholesale Faston Connectors, collaborating with us is a step towards enhancing your product offerings effectively.In-Depth Analysis of Methods China Top Faston Connector Factory From Concept to Delivery Sets the Industry Standard

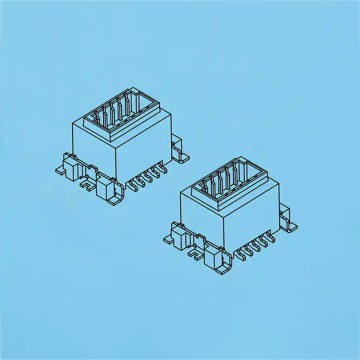

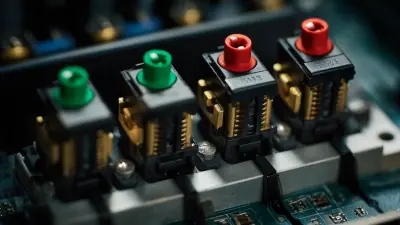

In the rapidly evolving world of Electrical Connectors, understanding the intricacies of manufacturing processes can significantly influence procurement decisions. Chinese faston connector factories are at the forefront of this industry, setting the standard from concept to delivery. Established in 2007, one of the leading private joint-stock enterprises has developed a robust infrastructure, with its factory spanning over 10,000 square meters and a total construction area exceeding 25,000 square meters. This extensive facility allows for streamlined operations and the capacity to meet high-volume orders while maintaining exceptional quality. The journey from concept to delivery in a top-notch connector factory involves several critical stages. First, a comprehensive design phase ensures that the connectors meet specific industry demands while focusing on innovation and efficiency. Modern manufacturing techniques, including automated production lines and rigorous quality control measures, further enhance the reliability of the products. As a result, global buyers benefit from connectors that not only meet but exceed industry standards, ensuring seamless integration into their applications. Moreover, logistical capabilities play a pivotal role in the effectiveness of a faston connector factory. With a dedicated team overseeing supply chain management, timely delivery is assured, allowing customers to maintain their project timelines without disruption. The combination of advanced technology, skilled workforce, and efficient logistics positions these factories as industry leaders, providing global procurement professionals with the confidence they need to make informed purchasing decisions.

In-Depth Analysis of Methods China Top Faston Connector Factory From Concept to Delivery Sets the Industry Standard

| Process Stage | Description | Key Technologies | Industry Standard Compliance | Lead Time (Days) |

|---|---|---|---|---|

| Concept Design | Initial design and prototyping of connectors. | CAD Software, 3D Printing | ISO 9001 | 15 |

| Material Selection | Choosing suitable materials for durability and performance. | Material Testing Equipment | RoHS Compliance | 10 |

| Manufacturing | Mass production of connectors using automated processes. | Injection Molding, CNC Machining | ISO 14001 | 20 |

| Quality Control | Ensuring all products meet required specifications. | Automated Testing Equipment | ISO/TS 16949 | 5 |

| Delivery | Final packaging and shipping of products to customers. | Logistics Management Software | Customs Compliance | 3 |

The Secret to China Top Faston Connector Factory Your Trusted OEM Partner Application

E

Elijah Sanders

Quality and professionalism shine through in their products and support team.

17 May 2025

R

Ryan Gomez

The products exceed expectations, and the service provided was impeccable!

25 May 2025

A

Aria Gray

The level of quality in the products is impressive! Support staff was incredibly knowledgeable.

18 June 2025

N

Nathan Young

Excellent quality! The support team handled my inquiries with great professionalism.

07 June 2025

A

Ava Lee

The quality of the products is incredible! Their team supported all my needs.

29 May 2025

S

Sophia Carter

Incredible product quality! The customer service made the difference.

29 May 2025