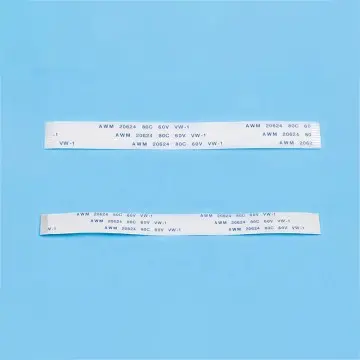

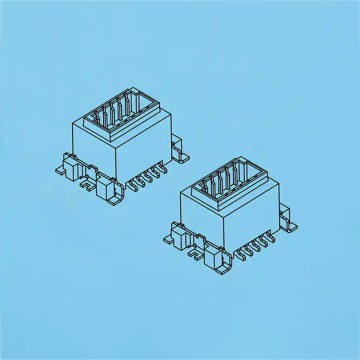

High-Quality Flat Flex Cable Connectors from Trusted Chinese Manufacturers & Suppliers

As a B2B purchaser in need of reliable components, I can attest that the Flat Flex Cable Connector delivers exceptional performance and versatility. This connector is designed to meet the demands of factories and manufacturers requiring high-quality connectivity. Its remarkable flexibility and durability make it suitable for tight spaces and complex assemblies. At Zhejiang Wenda Electronics Co., Ltd., quality is a top priority; our connectors undergo rigorous testing to meet industry standards, ensuring long-lasting performance. Sourcing from manufacturers who understand modern technology is essential, and Wenda excels in that regard. Having a range of options that cater to diverse needs, while upholding stringent manufacturing standards, makes these connectors a solid investment to achieve production goals effectively.Best Practices For Flat Flex Cable Connector Where Innovation Meets 2025 Pioneers in the Field

In the evolving landscape of technology, Flat Flex Cable Connectors have emerged as essential components, especially as industries strive for innovation and efficiency. As we approach 2025, understanding the best practices for integrating these connectors into advanced applications is crucial for procurement professionals across the globe. With the increasing demand for compact and flexible designs, manufacturers must prioritize cutting-edge engineering and quality assurance to meet the rigorous standards of modern electronics. One of the foundational best practices in the design and application of Flat Flex Cable Connectors is ensuring compatibility with various devices and circuits. Rigorous testing protocols should be implemented to evaluate flexibility, durability, and performance under different conditions. Additionally, collaboration between engineering and procurement teams can streamline the transition from design to production, reducing lead times and costs. It is essential to stay abreast of emerging technologies and materials that can enhance the functionality of flat flex connectors, such as heat resistance and improved signal integrity. Moreover, as industries shift towards sustainability, sourcing eco-friendly materials and implementing energy-efficient manufacturing processes in connector production will become increasingly pivotal. By prioritizing innovative approaches to minimize waste and enhance recyclability, manufacturers can not only meet regulatory requirements but also appeal to environmentally conscious buyers. Ultimately, bridging the gap between innovation and practical application in the realm of Flat Flex Cable Connectors will position companies at the forefront of their industries and cater to the evolving needs of global procurement professionals.

Best Practices For Flat Flex Cable Connector Where Innovation Meets 2025 Pioneers in the Field

| Best Practice | Description | Expected Outcome | Implementation Year |

|---|---|---|---|

| Rigorous Testing | Conduct extensive durability tests on Ffc Connectors. | Improved reliability and performance. | 2023 |

| Sustainability Practices | Embrace eco-friendly materials in production. | Reduced environmental impact and increased market appeal. | 2024 |

| Advanced Design Techniques | Utilize CAD software for precision in design. | Higher accuracy in dimensions increasing compatibility. | 2025 |

| Collaboration with Experts | Seek partnerships with material science experts. | Innovation in material usage leading to new products. | 2025 |

| Training and Development | Invest in continuous training for design engineers. | Enhanced skills leading to innovative connector solutions. | 2023 |

Step-by-Step Guide Flat Flex Cable Connector For the Current Year Where Service Meets Innovation

L

Liam Nelson

The products are fantastic! Customer service was prompt and reliable.

09 June 2025

S

Samantha Reed

Outstanding quality! The customer service took my experience to the next level.

27 June 2025

E

Elijah Sanders

Quality and professionalism shine through in their products and support team.

17 May 2025

H

Henry Torres

Outstanding! The quality is wonderful, and the team is incredibly skilled.

09 May 2025

S

Samantha Turner

Great experience! The product quality is high and support staff superb!

13 May 2025

Z

Zoe Allen

Outstanding quality! The support staff went the extra mile for me.

08 July 2025