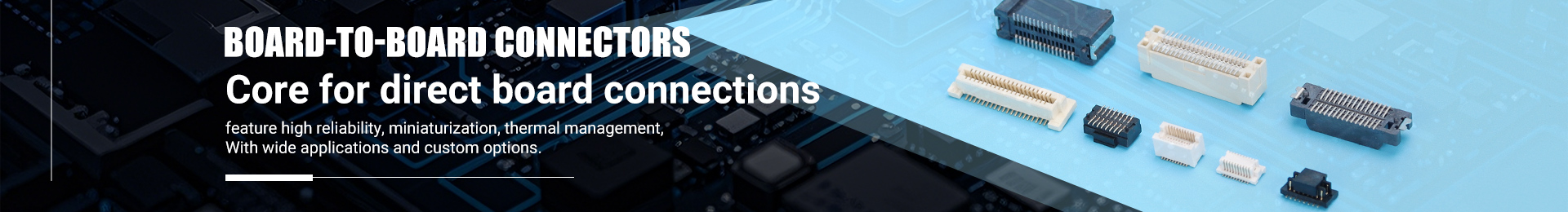

High-Quality Automotive Electrical Pins from Trusted Manufacturer Factory Online

As a buyer in the automotive industry, I recognize the need for high-quality electrical pins that meet strict standards. Our range of Automotive Electrical Pins provides dependable connections across various applications, ensuring optimal performance and safety. Partnering with Zhejiang Wenda Electronics Co., Ltd., a trusted supplier known for its quality and innovation, allows us to offer products that not only meet but consistently exceed market demands. Prioritizing durability and efficiency, these pins perform reliably under pressure. Our team is dedicated to supporting your needs, creating a seamless supply chain experience. Let’s discuss how our Automotive Electrical Pins can enhance your business operations.In-Depth Analysis of Methods Automotive Electrical Pins Guarantees Peak Performance Is The Best

In the ever-evolving automotive industry, ensuring peak performance through reliable components is non-negotiable. One critical yet often overlooked element is the quality of electrical pins. An in-depth analysis reveals several methods by which these vital components guarantee optimal performance in automotive applications. High-quality electrical pins minimize resistance, enhance conductivity, and ensure secure connections, thus preventing power losses and potential failures. The choice of materials, design features, and manufacturing processes all play a crucial role in achieving these standards. To ensure that Automotive Electrical Pins meet rigorous performance criteria, manufacturers must adopt advanced technologies and stringent quality control measures. Innovations such as precision machining and enhanced plating techniques contribute to improved durability and resistance to corrosion. Furthermore, a thorough understanding of the electrical environment in which these pins will operate allows for tailored solutions, such as ensuring compatibility with various operational temperatures and conditions. By prioritizing these factors, companies can offer products that not only comply with industry standards but also provide exceptional reliability and longevity. For global purchasers, collaborating with manufacturers that uphold these high standards offers a strategic advantage. As the industry gears towards electric and hybrid vehicles, the demand for top-notch electrical components continues to rise. Choosing a partner committed to delivering peak performance in Automotive Electrical Pins ensures that your supply chain remains robust, supporting not just current needs but also future innovations in vehicle design and technology.

In-Depth Analysis of Methods Automotive Electrical Pins Guarantees Peak Performance

| Method | Description | Benefits | Challenges |

|---|---|---|---|

| Crimping | Using a tool to deform a connector onto a wire for mechanical and electrical connection. | High reliability, low resistance, and good mechanical strength. | Requires precision tools and expertise. |

| Soldering | Joining electrical connections with melted solder to create a permanent bond. | Strong joint and excellent conductivity. | Can be labor-intensive and requires skill. |

| Mechanical Fastening | Using screws, bolts, or clips to secure electrical connections. | Easy to disassemble and service. | Potential for corrosion and loosening over time. |

| Connector Sealant | Use of special sealants or potting compounds to protect connections from moisture and contaminants. | Increased durability and resistance to environmental factors. | May complicate future repairs and maintenance. |

| Laser Welding | Joining metals using a laser beam for precise and strong connections. | Highly precise with a controlled heat-affected zone. | Requires specialized equipment and setup costs. |

Why China’s Automotive Electrical Pins Leads the Global Market Manufacturers You Can Rely On

E

Ethan Harris

Quality standards are high here. Customer service is well-trained and very helpful!

12 June 2025

B

Benjamin Cox

I value the quality of the goods. The professionalism of the staff truly stands out!

22 June 2025

O

Oliver Gonzalez

Professional staff and excellent quality. I couldn’t ask for more!

20 June 2025

H

Henry Torres

Outstanding! The quality is wonderful, and the team is incredibly skilled.

09 May 2025

C

Claire Peterson

Exceptional service! The products are well-made, and the team is super responsive.

14 May 2025

L

Logan Price

Quality is their hallmark. The customer service provided was outstanding!

11 May 2025