China's Leading Automotive Wiring Loom Manufacturer | Wholesale Supplier

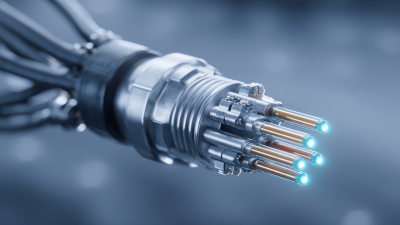

I specialize in high-quality Automotive Wiring Looms, catering to businesses in need of dependable suppliers. As a wholesale manufacturer based in China, I pride myself on being a leading provider in the industry. Our advanced factory is equipped with cutting-edge technology to ensure that every product adheres to strict quality standards. At Zhejiang Wenda Electronics Co., Ltd., we recognize the unique demands of the automotive sector, and my dedicated team works tirelessly to develop customized wiring solutions that enhance safety and performance. Partnering with us means gaining a committed team focused on your success. Feel free to reach out to learn more about our diverse range of Automotive Wiring Looms and how we can effectively collaborate to streamline your operations and drive your business forward.Methods To choose China Best Automotive Wiring Loom Factory Sets the Industry Standard For the Current Year

When it comes to selecting the best Automotive Wiring Loom factory in China, various methods can help procurement professionals make informed decisions that set industry standards for the current year. First and foremost, a thorough evaluation of the factory's production capabilities is essential. A facility with more than 10,000 square meters of operational space and extensive construction areas, indicative of a larger scale of operations, generally suggests that the factory can handle large orders and maintain high-quality standards consistently. Additionally, examining the workforce is crucial. A factory employing over 500 skilled workers is often a reflection of the expertise and efficiency required to produce complex automotive wiring solutions. Skilled personnel are vital in ensuring that manufacturing processes adhere to strict quality control measures, which are essential in an industry where reliability and safety are paramount. Procurement professionals should also consider the factory's technological capabilities, certifications, and past performance with other clients to gauge their reputation within the industry. Lastly, sustainability practices are becoming increasingly important in supplier selection. Factories that prioritize eco-friendly practices not only meet regulatory requirements but also appeal to a growing consumer preference for green products. By evaluating these criteria—production capacity, workforce expertise, technological advancement, and sustainability—buyers can choose a reputable Automotive Wiring Loom factory in China that sets the industry standard for quality and reliability in the current year.

Methods To Choose China Best Automotive Wiring Loom Factory Sets the Industry Standard For the Current Year

| Criteria | Description | Importance Level | Industry Standard |

|---|---|---|---|

| Quality Control | Evaluate the factory's quality assurance protocols and ISO certifications. | High | ISO 9001 |

| Production Capacity | Assess the maximum output the factory can produce per month. | Medium | 200,000 units/month |

| Technological Advancements | Evaluate if the factory employs modern manufacturing technologies. | High | Automation & Robotics |

| Customer Reviews | Analyze feedback from previous clients regarding reliability and service. | High | 90%+ Satisfaction Rate |

| Product Innovation | Check the factory's ability to innovate and develop new wiring solutions. | Medium | New Products Annually |

10 Essential Tips For China Best Automotive Wiring Loom Factory Is The Best Supplies the World’s Top Brands

R

Ryan Wright

Excellent craftsmanship and very professional support staff. A pleasure to work with!

25 June 2025

G

Grace Harris

Impressed by the craftsmanship! The support team was attentive and knowledgeable.

10 May 2025

C

Carter Bennett

The products are of great quality! The customer service was fantastic as well.

24 June 2025

D

Daniel Smith

Quality is great, and the support staff is excellent at what they do!

07 June 2025

O

Oliver Green

Great quality! The customer support team showed true professionalism.

10 May 2025

L

Lily Carter

Impressed by the product quality and the professionalism of their support staff.

20 May 2025