Top China Electrical Wiring Harness Manufacturers & Suppliers in 2023

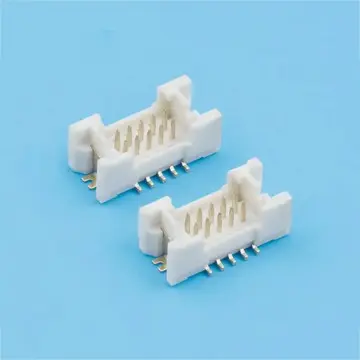

When sourcing high-quality Electrical Wiring Harnesses, partnering with a dependable manufacturer is essential. At Zhejiang Wenda Electronics Co., Ltd., we specialize in delivering exceptional products tailored to meet our clients' needs. Our modern factories in China are built to uphold the highest industry standards. We are committed to quality; each wiring harness undergoes thorough testing to ensure durability and performance. Our experienced team collaborates closely with clients to provide customized solutions that enhance their products.Methods To China Electrical Wiring Harness Factories Manufacturer Dominates

China has established itself as a leader in the manufacturing of Electrical Wiring Harnesses, a critical component in various industries including automotive, aerospace, and electronics. With a rich history of innovation and a robust industrial infrastructure, manufacturers in China have adopted effective strategies to dominate this market. One method is the integration of advanced technologies, such as automation and robotics, which significantly enhances production efficiency and quality control. This technology-driven approach allows manufacturers to swiftly adapt to changing demands while maintaining high standards. Another key factor is the scalability of production capabilities. Many Chinese factories are equipped with expansive facilities, often exceeding 25,000 square meters. This large-scale setup enables manufacturers to handle both bulk orders and customized solutions, catering to diverse client needs across the globe. Furthermore, significant investments in workforce training ensure that employees are well-versed in the latest manufacturing techniques, thereby fostering a culture of continuous improvement and innovation. Lastly, strong supply chain networks play a pivotal role in enhancing competitiveness on the international stage. Proximity to suppliers of raw materials and components allows for timely deliveries and reduced costs, which is essential for meeting the tight deadlines of global procurement managers. As a result, manufacturers in China are not just focused on producing wiring harnesses; they are committed to providing comprehensive solutions that add value for their clients, solidifying their status as preferred partners in the global market.

Methods To China Electrical Wiring Harness Factories Manufacturer Dominates

| Method | Description | Advantages | Challenges |

|---|---|---|---|

| Lean Manufacturing | Focus on minimizing waste while maximizing productivity. | Improved efficiency and cost reduction. | Requires cultural change and continuous monitoring. |

| Automation | Implementation of robotic systems for manufacturing processes. | Increased precision and production speed. | High initial investment costs and maintenance. |

| Supplier Relationship Management | Building long-term partnerships with suppliers for better cooperation. | Enhanced supply chain stability and quality. | Dependency on suppliers may increase risks. |

| Quality Control Systems | Implementation of rigorous testing and quality assurance processes. | Reduction of defects and improvement of product reliability. | Requires continuous training and system upgrades. |

| Just-In-Time Production | Producing goods as they are needed to reduce inventory costs. | Lower inventory costs and increased responsiveness to market demand. | Vulnerability to supply chain disruptions. |

Effective Ways To China Electrical Wiring Harness Factories Market Leader Global Reach

J

Jacob Martin

Unbelievable quality accompanied by strong customer support. Would recommend!

08 June 2025

N

Noah Wood

Excellent quality goods! Their after-sales support was exceptionally helpful.

07 June 2025

H

Hannah Hudson

Quality is top-of-the-line! The customer service really made my experience memorable.

14 May 2025

S

Sophie Scott

Incredible attention to detail in product quality. The support team was very helpful.

28 May 2025

N

Nathan Young

Excellent quality! The support team handled my inquiries with great professionalism.

07 June 2025

S

Sophia Carter

Incredible product quality! The customer service made the difference.

29 May 2025