Top Electrical Harness Manufacturers in China - Quality Suppliers and Factories

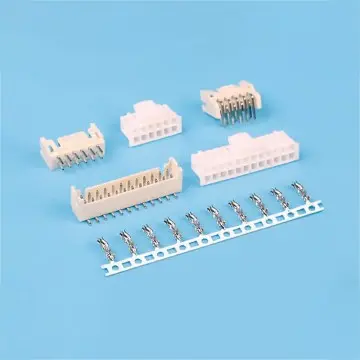

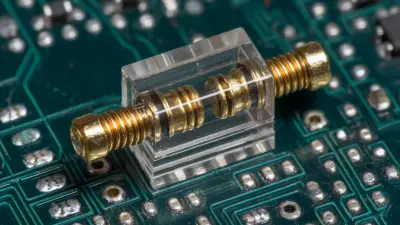

As a trusted leader in the Electrical Harness industry, we provide high-quality products directly from our factory. With years of expertise, we are recognized among China's top Electrical Harness manufacturers. Our dedication to excellence ensures that every wire and connector we produce meets stringent industry standards, providing reliability and performance for your projects. When partnering with us for wholesale Electrical Harness solutions, you gain a committed ally focused on your success. We offer a diverse range of customized options suitable for automotive, aerospace, and consumer electronics applications. Understanding the need for quick delivery and competitive pricing, we strive to offer the best value without compromising on quality. Partner with Zhejiang Wenda Electronics Co., Ltd. to experience the benefits of working with a factory that prioritizes your business needs. Together, we can create outstanding solutions.10 Essential Tips For China Leading Electrical Harness Factory For the Current Year in 2025

As we progress into 2025, the landscape of the Electrical Harness manufacturing industry in China continues to evolve, making it essential for global buyers to stay informed. One key factor is the significant growth in production capabilities. With state-of-the-art facilities spanning over 25,000 square meters, manufacturers can now offer a wider variety of products to meet the diverse needs of international clients. This increased capacity not only boosts production efficiency but also enhances quality control processes, ensuring that consumers receive the best products available. Moreover, sustainability practices are becoming increasingly vital in procurement decisions. Leading factories are adopting eco-friendly materials and energy-efficient manufacturing processes. This commitment to sustainability not only aligns with global environmental standards but also meets the rising consumer demand for responsible sourcing. Collaborating with manufacturers that prioritize environmental impact will not only benefit the planet but also resonate well with conscientious brands looking to enhance their corporate social responsibility profile. Lastly, establishing strong communication and collaboration channels with manufacturers is crucial. In an interconnected world, having a responsive partner who understands your specific needs can streamline the procurement process and lead to more successful outcomes. Buyers are encouraged to engage with their suppliers regularly, share insights, and provide feedback to cultivate a long-term relationship that can drive innovation and adaptability in an ever-changing market.

10 Essential Tips For China Leading Electrical Harness Factory For the Current Year in 2025

| Tip Number | Tip Description | Implementation Methods | Expected Outcomes |

|---|---|---|---|

| 1 | Invest in Advanced Machinery | Conduct market research and identify suitable technology | Increased production efficiency and quality |

| 2 | Enhance Employee Training | Implement ongoing skill development programs | Higher employee satisfaction and productivity |

| 3 | Focus on Sustainability | Adopt eco-friendly materials and practices | Improved brand image and compliance with regulations |

| 4 | Utilize Lean Manufacturing | Implement lean principles to minimize waste | Cost reduction and increased profitability |

| 5 | Strengthen Supply Chain Relationships | Build partnerships and communication channels | Robust supply chain and reduced lead times |

| 6 | Invest in R&D | Allocate funds for innovative projects | New product offerings and market differentiation |

| 7 | Emphasize Quality Control | Establish strict QC protocols and audits | Reduced defect rates and enhanced reputation |

| 8 | Leverage Digital Technologies | Implement IoT and automation technologies | Improved data accuracy and operational insights |

| 9 | Enhance Customer Service | Train staff in customer relations and support | Increased customer loyalty and retention |

| 10 | Monitor Industry Trends | Subscribe to industry analysis and reports | Proactive adaptation to market changes |

Key Steps to Choosing China Leading Electrical Harness Factory Manufacturers You Can Rely On Stands Out

O

Oliver Gonzalez

Professional staff and excellent quality. I couldn’t ask for more!

20 June 2025

J

James Turner

Exceptional quality and post-sale service! Highly skilled staff who genuinely care.

11 June 2025

L

Liam Coleman

The products are extremely reliable, complemented by knowledgeable customer service!

28 June 2025

H

Hannah Hudson

Quality is top-of-the-line! The customer service really made my experience memorable.

14 May 2025

N

Natalie Ramirez

The quality of the products is fantastic! Support was friendly and quick.

30 June 2025

O

Oliver Green

Great quality! The customer support team showed true professionalism.

10 May 2025